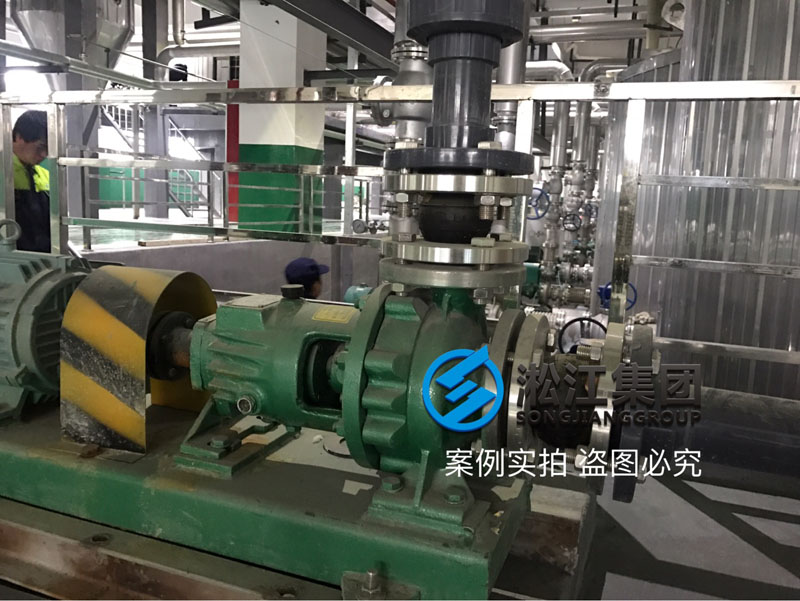

Shanghai Songjiang website presents: On-site usage information of EPDM rubber expansion joints, ‘Staying at our posts.’ Songjiang Group provides EPDM rubber expansion joint products for numerous chemical enterprises, playing a role in shock absorption and noise reduction. Below is the usage scene.

The project mainly utilizes EPDM rubber expansion joint products produced by Shanghai Songjiang, using stainless steel 304 flanges and EPDM rubber tubes. EPDM rubber, also known as Ethylene Propylene Diene Monomer, is resistant to high temperatures and acids and alkalis (weak acids and alkalis). Our EPDM products all use Mitsui 4045 from Japan, with a content of about 46%, supported by material certificates and third-party content testing reports. All stainless steel flanges are made of genuine 304 material, containing more than 8% nickel. They undergo spectroscopic testing before leaving the factory, and we also support various spectroscopic testing methods to ensure customers’ peace of mind in purchasing and using.

EPDM Introduction: Ethylene Propylene Diene Monomer (EPDM) is a terpolymer of ethylene, propylene, and a small amount of non-conjugated diene. It is a type of ethylene propylene rubber. EPDM is characterized by its chemical stability due to its main chain being composed of saturated hydrocarbons, with unsaturated double bonds only in the side chains. Therefore, it exhibits excellent aging resistance, heat resistance, and weather resistance, and it can be widely used in automotive components, waterproof materials for construction, wire and cable sheathing, heat-resistant hoses, tapes, automotive seals, and other fields.

EPDM rubber is a terpolymer of ethylene, propylene, and non-conjugated dienes, and commercial production began in 1963. The global consumption is 800,000 tons per year. The main characteristic of EPDM is its excellent oxidation, ozone resistance, and corrosion resistance. Since EPDM belongs to the polyolefin (PO) family, it has excellent vulcanization properties. Among all rubbers, EPDM has the lowest specific gravity and can absorb a large amount of fillers and oils without significant impact on its properties, making it possible to produce low-cost rubber compounds.

Related link: Stainless steel 304 flange rubber expansion joint