Shanghai Songjiang Vibration Absorber Group Co., Ltd. official website brings you information on the technical requirements for rubber expansion joints according to the Russian standard GOST12820-80. Songjiang Group provides high-quality rubber expansion joint products for numerous projects in Russia. Below are the technical requirements:

Technical Requirements for Russian Drilling Mud Rubber Expansion Joints

I. Product Name and Quantity: Rubber expansion joints with the following diameters:

- DY 300mm: 2 pieces

- DY 200mm: 2 pieces

- DY 150mm: 28 pieces

- DY 100mm: 8 pieces Compliant with Russian standard GOCT15150-69.

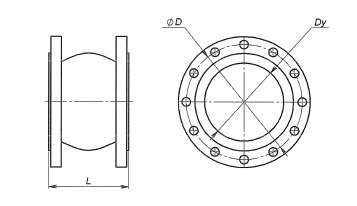

II. Technical Requirements: Linear dimensions L, diameter D, and DY diameter (unit: mm) of the fixed flange connection for each bolt hole are specified as follows:

- Rubber expansion joints with a diameter of DY 300mm have 12 bolt holes: L=205, D=410, DY=300.

- Rubber expansion joints with a diameter of DY 200mm have 12 bolt holes: L=205, D=295, DY=200.

- Rubber expansion joints with a diameter of DY 150mm have 8 bolt holes: L=180, D=240, DY=150.

- Rubber expansion joints with a diameter of DY 150mm have 8 bolt holes: L=150, D=180, DY=100. Note: The above flange linear dimensions should comply with Russian standard GOST12820-80.

III. Other Technical Requirements:

- Climate Usage Requirements: Operating temperature from -45°C to +60°C, storage temperature up to -60°C.

- Flanges should be galvanized.

- Working pressure: 1.6MPA.

- Must have Russian-issued permits, certificates of conformity, or Russian Customs Union certificates (any valid document is acceptable).

- Each provided product must have a certificate of conformity, and each sold product must have a certificate of conformity indicating the factory number.

- Each rubber expansion joint must have its own factory number, printed on the flange connection end.

- Rubber material for expansion joints is NBR (nitrile-butadiene rubber).

IV. Main Scope of Use:

- Mainly used in the circulation system of oil drilling rigs to compensate for the pressure, tension, axial displacement, lateral displacement, and vibration of pipelines. It should meet the requirements for drilling mud with a density of 2.2 k/cm3 and cementing water for well cementing.

- Operating environment should meet the requirements of extreme cold regions and comply with the standards of Climate Category 1 in Russian standard GOST 15150-69 (-45°C to +60°C, with a storage temperature of up to -60°C).

- Working conveying medium (drilling mud):

- Density of drilling mud not less than 2.2 k/cm3, pH value from 7 to 11, temperature from +4°C to +60°C, meeting the requirements for temperature and density of the main components of drilling mud, including water, petroleum, salt components, and synthetic chemicals.

- Other parameters of drilling mud: allowable residual natural gas content not exceeding 2%, viscosity from 10 to 150, solid content in the compensator up to 5%, hardness of solid particles not exceeding 3.

- The main chemical components of the drilling mud are: carboxymethyl cellulose sodium, polyacrylate, calcined sodium carbonate, silica, mud inhibitors, and polyacrylamide.

V. Product Requirements:

- Rubber expansion joints should ensure axial displacement of ±30mm, angular deflection of ±15°, and lateral displacement of ±70mm.

- Flanges should comply with Russian standard GOST12820-80, with a working pressure of 1.6MPA.

- The design working pressure of rubber balls should be 0.4MPa (factory test should be at 0.5MPa).

- Working media: water, drilling mud, and cement slurry for well cementing. Main impurities in the solid phase: sand, petroleum products, acidic substances, and polymers.

- Rubber ball manufacturing should use elastic materials.