Shanghai Songjiang Vibration Absorber Co., Ltd. is pleased to present information on SMS Schloemann-Siemag metal extrusion presses, widely recognized as a technical benchmark in the industry. Songjiang Group offers high-quality rubber expansion joints and metal bellows as dampening solutions for numerous metal extrusion presses. These products exhibit excellent hydraulic resistance and can withstand temperatures of up to 80 degrees Celsius, utilizing N41 rubber from China Petroleum Kunlun Brand. They have been successfully employed in metal extrusion presses of 125MN, 150MN, and 225MN models.

- Introduction to Metal Extrusion Presses: Metal extrusion presses are the primary equipment for producing tubes, bars, and profiles of light alloys (aluminum, copper, and magnesium). The evolution of extrusion presses has seen remarkable changes over more than a century, from manually operated hydraulic presses to fully automatic oil presses with a capacity of up to two hundred meganewtons. The variety of extrusion presses reflects a company’s technological prowess, while a nation’s industrial development is mirrored in its capacity, quantity, production capabilities, and equipment level of extrusion presses.

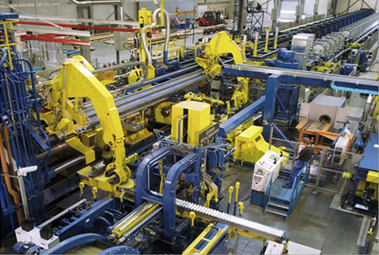

Metal extrusion presses manufactured by the German SMS Group stand out as an undisputed technical benchmark in the industry! SMS Group is the only global manufacturer capable of producing extrusion presses for all types of metals and alloys, along with providing all auxiliary equipment and automation systems. With over 1400 applications worldwide, SMS Group’s professional expertise and strength are well demonstrated. The unique front loading structure design, coupled with advanced extrusion technology, ensures exceptional industry quality while integrating high productivity and stability.

Typical applications include extruding aluminum alloy profiles and tubes for automotive, aerospace, and construction sectors. Equipped with long-life stacked plate upright columns, high-precision linear guidance systems, advanced energy-saving hydraulic designs, and user-friendly process control software, SMS Schloemann-Siemag extrusion presses are undisputed leaders in industry technology.

- Forward Extrusion Press: This is a common machine type, suitable for single or double action extrusion, ideal for small-batch production with frequent alloy changes. All models feature SMS Schloemann’s unique front loading structure design and classic Schloemann stacked plate pre-tensioning columns, ensuring higher frame stiffness for better profile quality and extended service life.

Nominal Extrusion Force: 8 – 160 MN Maximum Aluminum Ingot Length: 630 – 2500 mm Minimum/Maximum Extrusion Speed: 0.1 – 30 mm/s

- Backward Extrusion Press: Primarily used for indirect extrusion of series 2 and 7 hard alloys, in single or double action extrusion, the absence of friction between the aluminum ingot and the extrusion cylinder allows for lower extrusion force and more uniform material flow, making it particularly suitable for extruding high-strength alloys. These presses can also offer forward and backward extrusion switching capabilities to better meet market demands.

Nominal Extrusion Force: 10 – 150 MN Maximum Aluminum Ingot Length: 550 – 2000 mm Minimum/Maximum Extrusion Speed: 0.1 – 20 mm Speed Closed-loop Control Precision: ± 0.05 mm/s

- Copper Extrusion Production Line: Comprising both forward and backward extrusion machine types, the backward extrusion press is primarily used for extruding rods and wires due to its ability to extrude longer copper ingots, significantly increasing productivity. The forward extrusion press is mainly used for extruding tubes. Combined forward and backward extrusion presses are available to meet diverse product requirements.

Nominal Extrusion Force: 16 – 150 MN Includes fully automatic rear copper wire auto-coiling system and tube handling system Fully automatic auxiliary systems (robots)

- Steel Extrusion Production Line: Mainly used for extruding steel, high-strength alloys, nickel-based alloys, titanium, zirconium profiles, and seamless tubes. High-speed extrusion is employed to reduce the contact time between high-temperature materials and the extrusion die, thereby extending the die’s service life within the permissible metal deformation temperature window. Equipped with high-pressure accumulator systems, the extrusion shaft speed can reach up to 400 mm/s. To extend die life, glass lubrication technology and perforation needle cooling technology are necessary when extruding seamless steel tubes, often requiring a vertical perforating machine for pre-piercing steel billets.

Nominal Extrusion Force: 8 – 70 MN Horizontal Extrusion Press and Vertical Perforating Machine Fully automatic auxiliary systems Metal extrusion presses are the primary equipment for metal extrusion processing, utilizing the plasticity of metals for shaping. It is an essential method for transforming metal ingots into tubes, rods, and profiles almost instantaneously, with hardly any other method matching its efficiency. Metal extrusion finds extensive applications in various fields, from the construction materials of beautiful and elegant buildings to the backbone materials of aircraft flying across continents and oceans, spacecraft exploring outer space, and vehicles including railways, subways, light rails, maglev trains, ships, and speedboats.

6.Introduction to Rubber Expansion Joints for SMS Schloemann-Siemag Metal Extrusion Presses:

The above information on SMS Schloemann-Siemag metal extrusion presses as an undisputed technical benchmark in the industry is sourced from the official website of Shanghai Songjiang Vibration Absorber Group Co., Ltd. Songjiang Group offers high-quality rubber expansion joints for numerous metal extrusion presses. These expansion joints exhibit excellent hydraulic resistance and can withstand temperatures of up to 80 degrees Celsius, utilizing N41 rubber from China Petroleum Kunlun Brand. These products have been successfully employed in metal extrusion presses of 125MN, 150MN, and 225MN models.

Related links:LO Type Hydraulic Rubber Expansion joints