The official website of Shanghai Songjiang Vibration Absorber Group Co., Ltd. is pleased to share information about the smooth progress of the construction of Songjiang Group’s Nantong factory. In response to national environmental policies, Songjiang Group has relocated its entire Shanghai factory to the Shuangdian Industrial Concentration Zone in Nantong. The new factory is equipped with advanced environmental protection equipment to ensure pollution-free, harmless, and sustainable development.

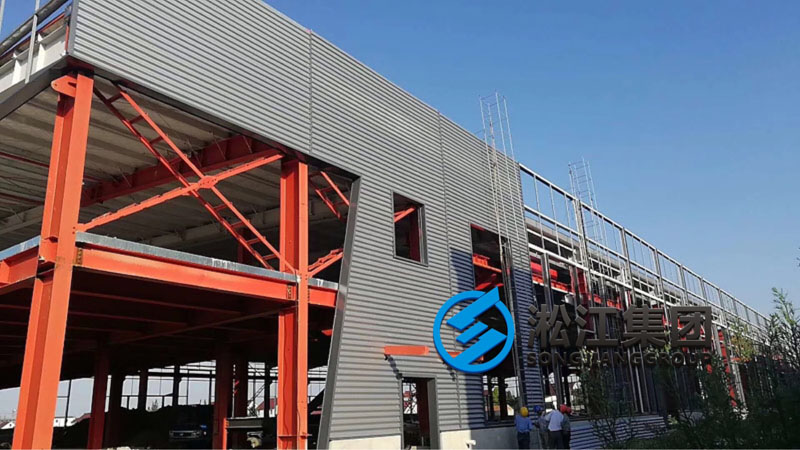

Below are on-site photos taken by Songjiang Group’s editors at the construction site of the Nantong factory. Please do not reproduce without permission. Thank you for your cooperation.

The exterior design adopts the decoration style of German Audi 4S stores, appearing simple, generous, neat, and fashionable. The internal floor hardening has been basically completed.

Preparation work before floor hardening:

Internal distribution room in the workshop, fireproof partition:

Part of the workshop has been fully completed:

The rubber compounding workshop requires a cooling pit. Below is the excavation site of the cooling pit:

In this area of Nantong, the ground level is low, and digging slightly deeper would reach water. Therefore, a drainage system needs to be arranged. After the drainage system is set up, the excavator can start working:

All cooling pits are constructed of concrete:

Completion of the cooling pit:

According to the project manager on-site, the internal floor hardening of the Songjiang Group’s Nantong factory has been completed, and several cooling pits have also been completed. The steel wall and roof of the workshop have been finished, and the next steps involve the installation of glass curtain walls and all windows. The fire protection system has just started construction, and the water and electricity systems have also just begun construction. It is expected to be fully completed by October 2018 and enter the overall acceptance phase.

The Songjiang Group’s Nantong factory will be fully operational in 2019. We welcome new and old customers to visit and inspect the factory. This time, Songjiang Group will invest in a large number of modern and automated production equipment, phasing out traditional equipment, reducing labor costs, and improving production efficiency to ensure the stability of product quality. The production workshop mainly includes automatic weighing equipment, automatic feeding equipment, automatic mixing equipment, automatic molding equipment, and automatic vulcanization equipment. The laboratory will be equipped with equipment such as raw material testing, sampling testing, specimen testing, finished product pressure testing, finished product performance testing, finished product fatigue testing, and special performance testing equipment for oil resistance, high temperature resistance, acid and alkali resistance, etc., to ensure that customers can purchase and use with confidence.