Shanghai Songjiang Shock Absorber Group Co., Ltd. has officially released the core information of the rubber joint contract for the [Phase I Clean Energy Demonstration Project of Changchun Nanxi Zhirong Project] on its official website. As a leading enterprise in the industry, Songjiang Group, with its profound technical accumulation and rich project experience, has been committed to custom – making high – quality rubber joints for urban clean energy projects for a long time. Its product quality has established extremely high reliability and credibility in the industry.

I. Rubber Joints: High – Quality Materials and Excellent Performance

(I) Materials and Manufacturing Processes

Songjiang Group adheres to strict standards in raw material selection for its rubber joints. The joints are made of 100% pure natural rubber, with no recycled rubber added. Pure natural rubber endows the joints with excellent high elasticity, remarkable wear resistance, and excellent aging resistance, ensuring stable physical properties in long – term and complex working conditions.

For the connecting components, the flanges are carefully selected from carbon steel flanges or galvanized flanges. Carbon steel flanges have high strength and good rigidity, capable of withstanding large pressures and tensions. Galvanized flanges, on the basis of carbon steel flanges, are coated with a zinc – plating layer, significantly improving corrosion resistance and effectively resisting the erosion of various chemical media. This careful material selection fundamentally guarantees the tightness, sealing performance, and long – term stability of the connection between the joints and the pipelines.

During the production process, Songjiang Group strictly follows international advanced manufacturing process standards. The rubber material first undergoes precise formula modulation to ensure the optimal balance of various performance indicators. Then, through the high – precision mold – forming process, the dimensional error of each rubber joint is controlled within a very small range. The subsequent high – temperature vulcanization process is a crucial step in determining the performance of the rubber joint. By precisely controlling parameters such as vulcanization temperature, time, and pressure, the rubber molecules undergo a cross – linking reaction to form a stable three – dimensional network structure, thus possessing excellent physical and chemical properties. Each rubber joint undergoes strict multi – dimensional quality inspections before leaving the factory, covering multiple indicators such as dimensional accuracy, hardness, tensile strength, tear strength, and resistance to media, ensuring full compliance with high – standard quality requirements.

(II) Vibration Isolation Advantages

Rubber joint vibration isolators play an indispensable and crucial role in this project. During the operation of air – source heat pump equipment and pipeline systems, vibrations and noises are inevitably generated. Rubber joint vibration isolators, with their unique structural design and rubber material properties, can efficiently isolate and absorb this vibration energy.

The internal rubber elastomer acts like an efficient energy buffer. When vibrations are transmitted to the rubber joint, the rubber molecules convert the vibration energy into heat energy through their elastic deformation and dissipate it, thereby greatly reducing the vibration transmission rate. This vibration isolation effect not only reduces the impact of vibrations on the building structure, avoiding structural fatigue, loosening, and even damage caused by long – term vibrations, but also effectively reduces vibration interference to the surrounding environment.

In terms of noise reduction, rubber joint vibration isolators also perform excellently. By reducing vibration transmission, they fundamentally reduce the noise radiation caused by vibrations. At the same time, the rubber material itself has a certain sound – absorbing performance, which can further absorb and attenuate noise, creating a quiet and comfortable environment for the project area. Professional tests have shown that after using Songjiang Group’s rubber joint vibration isolators, the noise level in the project area can be significantly reduced, effectively improving the overall user experience and environmental quality. In addition, a stable operating environment can also significantly extend the service life of equipment and pipelines, reducing maintenance costs and replacement frequencies, and providing a solid guarantee for the long – term stable operation of the project.

II. Overview of the Phase I Clean Energy Demonstration Project of Nanxi Zhirong Project

The Changchun Municipal Bureau of Planning and Natural Resources has released a public notice regarding the adjustment of the engineering plan for the Phase I of the Nanxi Zhirong Project. The project is strategically located east of Renmin Street and next to Changchun No. 2 Experimental Middle School. The Phase I project covers a planned area of 55,900 square meters, with a total construction area of 164,000 square meters, a floor – area ratio of 2.91, and 1,332 planned parking spaces. This plan adjustment involves the optimization of the internal functional layout, spatial pattern, and construction area of multiple buildings. After the adjustment, the construction area of the Phase I project has ultimately increased by 74.28 square meters, and the floor – area subject to calculation has increased by 2,863.08 square meters, while key indicators such as the floor – area ratio and the number of parking spaces remain unchanged.

(I) Basic Project Information

Project Name: Operation and Management of Air – Source Thermal Energy for the Phase I Clean Energy Demonstration Project of Nanxi Zhirong Project.

Project Scale: Responsible for the operation and management of air – source thermal energy for Buildings 2457 – 12151617 in the Phase I of the Nanxi Zhirong Project. The total construction area of the project is tentatively 90,257.87 square meters. The final construction area of equipment and facilities shall be based on the area marked on the project’s house property certificate. For the heating management area, the area marked on the house property certificate shall be used for houses with property rights. For areas such as underground garages and restaurants that cannot obtain property certificates, the construction area marked on the construction project planning permit shall be used.

Construction Location: The project is located in Nanguan District, Changchun, specifically on the plot east of the intersection of Renmin Street and South Fourth Ring Road. Its four boundaries are clearly defined: east to Bingyibai Road, west to Renmin Street, south to Yiqi Road, and north to Bingjiujiu Road.

(II) Bidding Content

This bidding covers the comprehensive operation and management services of air – source thermal energy in this area. Specifically, it includes using advanced air – source heating and cooling systems to achieve efficient heating and cooling in the park, providing a comfortable indoor environment for users in the park. At the same time, by leveraging the intelligent smart energy management platform, real – time linkage and in – depth optimization of the regional energy system are realized. Through the precise collection, analysis, and processing of energy data, energy resources are reasonably allocated, energy utilization efficiency is improved, and energy consumption and operating costs are reduced.

In terms of equipment and facilities, it is responsible for the procurement and installation of the overall facilities and systems in the outdoor air – source heat pump equipment and the cold – heat source station. Every step, from equipment selection, supplier evaluation to installation and commissioning, is strictly carried out in accordance with high standards to ensure that the performance and quality of the equipment reach the best state. In addition, it also undertakes the daily operation, regular maintenance, professional servicing, and timely replacement of all equipment and facilities. During the management period, except for cases of deliberate man – made damage, all operation, maintenance, and repair costs, including but not limited to the electricity, water, and labor costs generated by the operation of the cold – heat source station and the main engine, as well as the costs of equipment maintenance, servicing, repair, and replacement, shall be borne by Party B. After the operation period, the ownership of all equipment and facilities shall be transferred to Party A.

(III) Management Period

The construction phase requires the completion of all project construction within 70 days after the formal signing of the contract and ensures that the project meets the heating conditions and can be put into use on schedule. The operation period is set for 20 years, from October 1, 2023, to September 30, 2043. The start time of the operation period shall be based on the date of the successful completion and acceptance of the overall project. If the above – mentioned agreed date is inconsistent with the actual date of successful completion and acceptance, the actual acceptance date shall be used as the start – calculation time for the operation period. During the operation period, the ownership of all equipment involved in the project’s operation and management shall belong to Party B to ensure the effective management and operation of the equipment by Party B. After the operation period, the ownership of all equipment shall officially belong to Party A.

III. Contract Document Display

(I) Contract Scan

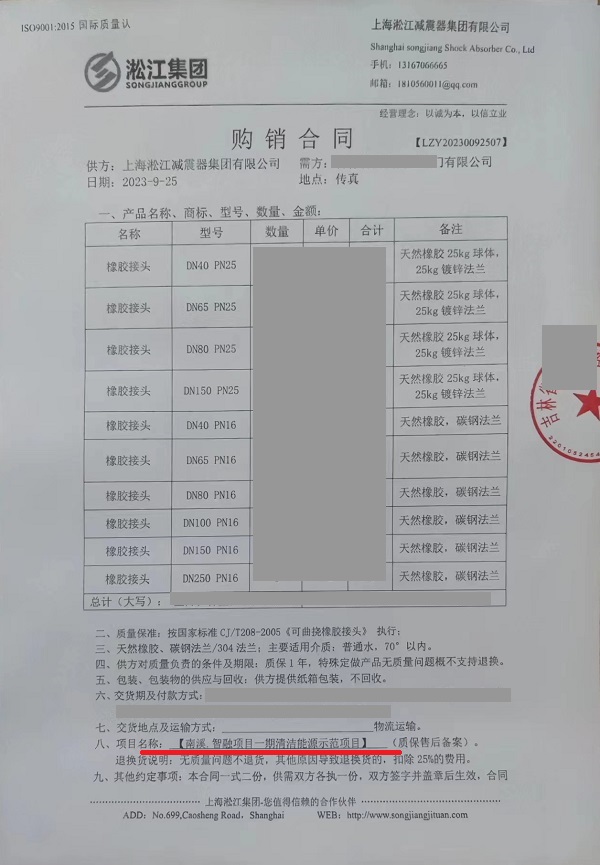

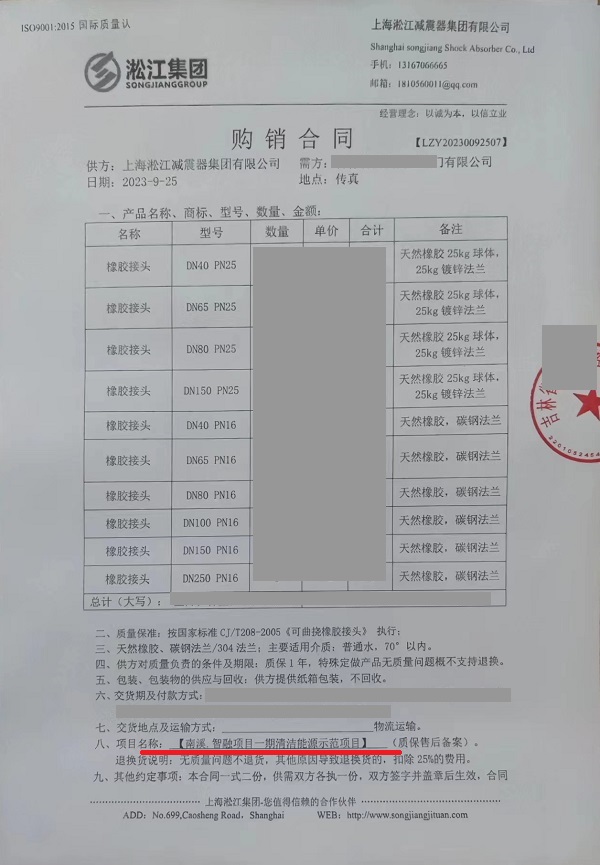

To ensure the transparency and traceability of the cooperation, we provide a detailed scan of the rubber joint contract for the [Phase I Clean Energy Demonstration Project of Nanxi Zhirong Project]. This scan fully presents all the contract terms, detailed product specifications, clear delivery time nodes, and other key information, enabling both parties to have a clear understanding of the cooperation details at a glance and providing a solid written basis for the smooth progress of the cooperation.

(II) Contract Delivery Photos

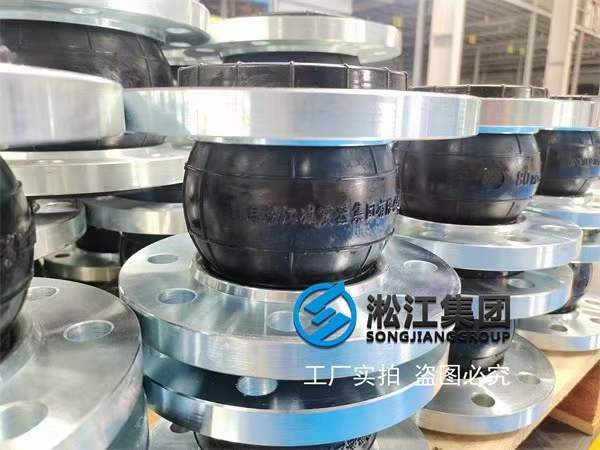

At the same time, we attach high – definition photos of the on – site contract delivery, visually demonstrating the rigorous logistics process of product delivery from the factory to the project site. Each photo witnesses the high – quality delivery process of the products. From product packaging protection, loading and fixing to transportation scheduling, every step reflects our strict control over product quality and delivery services, allowing customers to truly feel our high sense of responsibility and professional attitude towards the project.

I. Rubber Joints: High – Quality Materials and Excellent Performance

(I) Materials and Manufacturing Processes

Songjiang Group adheres to strict standards in raw material selection for its rubber joints. The joints are made of 100% pure natural rubber, with no recycled rubber added. Pure natural rubber endows the joints with excellent high elasticity, remarkable wear resistance, and excellent aging resistance, ensuring stable physical properties in long – term and complex working conditions.

For the connecting components, the flanges are carefully selected from carbon steel flanges or galvanized flanges. Carbon steel flanges have high strength and good rigidity, capable of withstanding large pressures and tensions. Galvanized flanges, on the basis of carbon steel flanges, are coated with a zinc – plating layer, significantly improving corrosion resistance and effectively resisting the erosion of various chemical media. This careful material selection fundamentally guarantees the tightness, sealing performance, and long – term stability of the connection between the joints and the pipelines.

During the production process, Songjiang Group strictly follows international advanced manufacturing process standards. The rubber material first undergoes precise formula modulation to ensure the optimal balance of various performance indicators. Then, through the high – precision mold – forming process, the dimensional error of each rubber joint is controlled within a very small range. The subsequent high – temperature vulcanization process is a crucial step in determining the performance of the rubber joint. By precisely controlling parameters such as vulcanization temperature, time, and pressure, the rubber molecules undergo a cross – linking reaction to form a stable three – dimensional network structure, thus possessing excellent physical and chemical properties. Each rubber joint undergoes strict multi – dimensional quality inspections before leaving the factory, covering multiple indicators such as dimensional accuracy, hardness, tensile strength, tear strength, and resistance to media, ensuring full compliance with high – standard quality requirements.

(II) Vibration Isolation Advantages

Rubber joint vibration isolators play an indispensable and crucial role in this project. During the operation of air – source heat pump equipment and pipeline systems, vibrations and noises are inevitably generated. Rubber joint vibration isolators, with their unique structural design and rubber material properties, can efficiently isolate and absorb this vibration energy.

The internal rubber elastomer acts like an efficient energy buffer. When vibrations are transmitted to the rubber joint, the rubber molecules convert the vibration energy into heat energy through their elastic deformation and dissipate it, thereby greatly reducing the vibration transmission rate. This vibration isolation effect not only reduces the impact of vibrations on the building structure, avoiding structural fatigue, loosening, and even damage caused by long – term vibrations, but also effectively reduces vibration interference to the surrounding environment.

In terms of noise reduction, rubber joint vibration isolators also perform excellently. By reducing vibration transmission, they fundamentally reduce the noise radiation caused by vibrations. At the same time, the rubber material itself has a certain sound – absorbing performance, which can further absorb and attenuate noise, creating a quiet and comfortable environment for the project area. Professional tests have shown that after using Songjiang Group’s rubber joint vibration isolators, the noise level in the project area can be significantly reduced, effectively improving the overall user experience and environmental quality. In addition, a stable operating environment can also significantly extend the service life of equipment and pipelines, reducing maintenance costs and replacement frequencies, and providing a solid guarantee for the long – term stable operation of the project.

II. Overview of the Phase I Clean Energy Demonstration Project of Nanxi Zhirong Project

The Changchun Municipal Bureau of Planning and Natural Resources has released a public notice regarding the adjustment of the engineering plan for the Phase I of the Nanxi Zhirong Project. The project is strategically located east of Renmin Street and next to Changchun No. 2 Experimental Middle School. The Phase I project covers a planned area of 55,900 square meters, with a total construction area of 164,000 square meters, a floor – area ratio of 2.91, and 1,332 planned parking spaces. This plan adjustment involves the optimization of the internal functional layout, spatial pattern, and construction area of multiple buildings. After the adjustment, the construction area of the Phase I project has ultimately increased by 74.28 square meters, and the floor – area subject to calculation has increased by 2,863.08 square meters, while key indicators such as the floor – area ratio and the number of parking spaces remain unchanged.

(I) Basic Project Information

Project Name: Operation and Management of Air – Source Thermal Energy for the Phase I Clean Energy Demonstration Project of Nanxi Zhirong Project.

Project Scale: Responsible for the operation and management of air – source thermal energy for Buildings 2457 – 12151617 in the Phase I of the Nanxi Zhirong Project. The total construction area of the project is tentatively 90,257.87 square meters. The final construction area of equipment and facilities shall be based on the area marked on the project’s house property certificate. For the heating management area, the area marked on the house property certificate shall be used for houses with property rights. For areas such as underground garages and restaurants that cannot obtain property certificates, the construction area marked on the construction project planning permit shall be used.

Construction Location: The project is located in Nanguan District, Changchun, specifically on the plot east of the intersection of Renmin Street and South Fourth Ring Road. Its four boundaries are clearly defined: east to Bingyibai Road, west to Renmin Street, south to Yiqi Road, and north to Bingjiujiu Road.

(II) Bidding Content

This bidding covers the comprehensive operation and management services of air – source thermal energy in this area. Specifically, it includes using advanced air – source heating and cooling systems to achieve efficient heating and cooling in the park, providing a comfortable indoor environment for users in the park. At the same time, by leveraging the intelligent smart energy management platform, real – time linkage and in – depth optimization of the regional energy system are realized. Through the precise collection, analysis, and processing of energy data, energy resources are reasonably allocated, energy utilization efficiency is improved, and energy consumption and operating costs are reduced.

In terms of equipment and facilities, it is responsible for the procurement and installation of the overall facilities and systems in the outdoor air – source heat pump equipment and the cold – heat source station. Every step, from equipment selection, supplier evaluation to installation and commissioning, is strictly carried out in accordance with high standards to ensure that the performance and quality of the equipment reach the best state. In addition, it also undertakes the daily operation, regular maintenance, professional servicing, and timely replacement of all equipment and facilities. During the management period, except for cases of deliberate man – made damage, all operation, maintenance, and repair costs, including but not limited to the electricity, water, and labor costs generated by the operation of the cold – heat source station and the main engine, as well as the costs of equipment maintenance, servicing, repair, and replacement, shall be borne by Party B. After the operation period, the ownership of all equipment and facilities shall be transferred to Party A.

(III) Management Period

The construction phase requires the completion of all project construction within 70 days after the formal signing of the contract and ensures that the project meets the heating conditions and can be put into use on schedule. The operation period is set for 20 years, from October 1, 2023, to September 30, 2043. The start time of the operation period shall be based on the date of the successful completion and acceptance of the overall project. If the above – mentioned agreed date is inconsistent with the actual date of successful completion and acceptance, the actual acceptance date shall be used as the start – calculation time for the operation period. During the operation period, the ownership of all equipment involved in the project’s operation and management shall belong to Party B to ensure the effective management and operation of the equipment by Party B. After the operation period, the ownership of all equipment shall officially belong to Party A.

III. Contract Document Display

(I) Contract Scan

To ensure the transparency and traceability of the cooperation, we provide a detailed scan of the rubber joint contract for the [Phase I Clean Energy Demonstration Project of Nanxi Zhirong Project]. This scan fully presents all the contract terms, detailed product specifications, clear delivery time nodes, and other key information, enabling both parties to have a clear understanding of the cooperation details at a glance and providing a solid written basis for the smooth progress of the cooperation.

(II) Contract Delivery Photos

At the same time, we attach high – definition photos of the on – site contract delivery, visually demonstrating the rigorous logistics process of product delivery from the factory to the project site. Each photo witnesses the high – quality delivery process of the products. From product packaging protection, loading and fixing to transportation scheduling, every step reflects our strict control over product quality and delivery services, allowing customers to truly feel our high sense of responsibility and professional attitude towards the project.

Our company’s new website is now live, featuring the latest product introductions. For more details, please visit http://www.shsjflex.com