The official website of Shanghai Songjiang Group introduces information about the role of rubber expansion joints in modular chiller plants. Songjiang Group provides vibration reduction and noise reduction solutions for numerous modular chiller plants and supplies high-quality rubber expansion joint products.

First, let’s understand what modular chiller plants are:

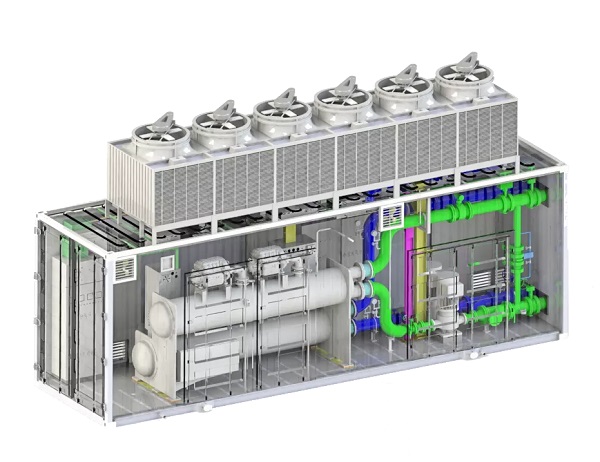

The design of modular chiller plants focuses on system integration, which is the core of modular chiller plant optimization. The essence lies in achieving the optimal overall performance of the system, where all components and elements work together not only efficiently but also economically, effectively, expandably, and maintainably as an integrated system. By utilizing system integration technology, modular chiller plants correlate and match various components of the chiller plant, enabling the coordinated operation of all equipment within the chiller plant to achieve optimal overall performance. Modular chiller plant design includes optimization and matching of chiller plant equipment, detailed pipeline design, overall structural design, structural simulation verification, and control system design. System integration of chiller plants involves more than simple supply and assembly of component equipment. It utilizes system integration technology to select and match equipment types and parameters based on detailed requirements and considerations of modular chiller plant design technology, inherent characteristics, and operational performance of equipment such as chillers, chilled water pumps, cooling water pumps, cooling towers, etc., to achieve optimal overall performance of the chiller plant.

The overall structural design of modular chiller plants mainly includes overall layout, system optimization, pipeline arrangement, control system layout, support and bracket design, module division, and three-dimensional simulation of chiller plant spatial structure. Structural simulation and verification involve rational design and verification of key load-bearing components such as pipelines, supports, and base structures to ensure safety, reliability, vibration reduction, and noise reduction during operation.

The design of the control system mainly involves in-depth design of the control system’s software and hardware structure and functions based on equipment selection, spatial layout of the chiller plant, and requirements of data center air conditioning systems. It can detect the operating status of chiller plant equipment in real-time, quickly identify faults, automatically control, and reduce human errors. The control system evolves from single-point PID control to correlation predictive control, enabling coordinated control of various equipment within the chiller plant to reduce overall energy consumption of integrated chiller plant systems.

The Role of Rubber Expansion Joints in Modular Chiller Plants:

Rubber expansion joints are primarily used at the inlet and outlet of chiller units in modular chiller plants to reduce vibration and noise, effectively protecting the long-term stable operation of chiller units, preventing the transmission of equipment vibration noise, and avoiding pipe rupture caused by vibration.

![[Shanxi Kangwei Hongtai Coal Washing Plant] Rubber Expansion Joint Contract](https://www.sungkiangflex.com/wp-content/themes/sj-1/timthumb.php?src=https://www.sungkiangflex.com/wp-content/uploads/2024/06/Shanxi-Kangwei-Hongtai-Coal-Washing-Plant-Rubber-Expansion-Joint-Contract-1.jpg&h=300&w=400&zc=1)