Shanghai Songjiang Vibration Absorber Co., Ltd.’s official website presents information on the role of rubber expansion joints in pressurized direct heating equipment. Songjiang Group’s rubber expansion joints offer excellent shock absorption and noise reduction effects. Installing rubber expansion joints effectively protects the long-term stable operation of pressurized direct heating equipment, preventing pipe system fractures caused by long-term vibrations and significantly reducing vibration and noise, thus eliminating disturbances.

Role of Rubber Expansion Joints in Pressurized Direct Heating Equipment:

Introduction to Pressurized Direct Heating Equipment: High-rise building direct heating equipment is a new technology product developed by our company. It directly connects the high-zone heating system with the low-zone heating system of high-rise buildings. Compared to traditional high-rise building heating systems, it eliminates the need for heat exchangers, dedicated boilers for high zones, and water tanks. This equipment directly pressurizes the hot water supply to the high zone and connects the high zone return water with the low zone return water after pressure reduction. This avoids the large heat loss of the heat exchanger system and the serious corrosion of pipelines and equipment caused by the open-loop system with dual water tanks. High-rise building direct heating equipment provides us with a structurally simple, low-investment, high-efficiency, fully automatic heating system. With the increasing number of high-rise buildings in China, this equipment has gradually become the preferred heating system for high-rise buildings, with broad application prospects.

Features of Pressurized Direct Heating Equipment:

- Energy savings of over 30%-50%: By fully utilizing the original pressure of the municipal heating network and employing intelligent variable frequency technology, continuous or timed variable speed operation can be achieved.

- Over 60% investment savings: By directly paralleling with the municipal heating network, substantial investments in building mechanical rooms are saved, eliminating the need for softening equipment, dedicated water tanks for pressure-compensating makeup water units, and more, thus saving a significant amount of equipment investment.

- Energy conservation: By eliminating the heat exchange process and adding an automatic mixed water system, the thermal efficiency approaches 100%, increasing the heat utilization rate by 15%-20%, while reducing the investment in heating area radiator facilities and achieving good heating effects.

- Intelligent and advanced control system: Utilizing an intelligent interface control system with simple operation and aesthetically pleasing interface, it displays relevant parameters and operating status in real-time, enabling remote and wireless monitoring.

- Initial investment savings: Conventional heating methods require the construction of heat exchange stations, with construction costs ranging from hundreds of thousands to millions. This method not only requires significant capital investment but also leads to heat energy loss, resulting in unnecessary energy waste.

- Stable operation: The high and low zones do not interfere with each other, and the pressure and flow control of the high zone heating system are portable, allowing different operating conditions to be determined according to actual needs. Advanced technology and high-quality guaranteed equipment ensure long-term stable operation.

- Small footprint: Designed as integrated units, they can be easily installed in equipment rooms without occupying additional space within high-rise buildings.

- Wide range of applications: Suitable not only for new construction projects but also for grid-connected renovations, the application of this equipment requires no modifications to the building’s internal heating system.

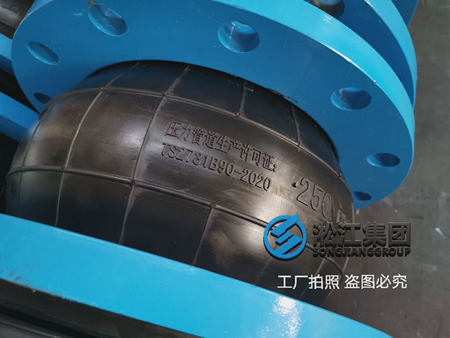

Related links:DN250 High-Temperature Resistant Rubber Expansion Joint for ‘Direct Heating’