Key factors for installation of rubber expansion joint

Following advice must be taken into consideration to ensure good performance and prolonged lifespan of the expansion joint.

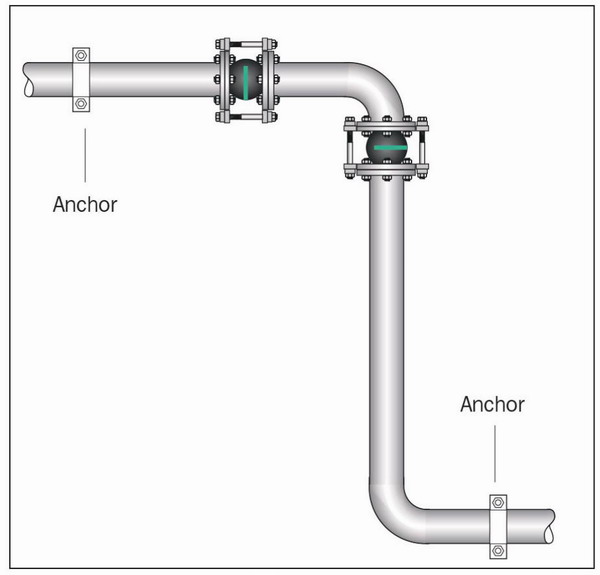

Fixed points

An expansion joint acts as a piston due to the forces generated by internal pressure. To prevent damage to the pipes, they must be properly anchored to handle these reaction forces (Fr).

The reaction force of an expansion joint is calculated by the following formula: Fr = Q x P x 0.01 Fr = Reaction force, measured in kilonewtons (kN). Q = Effective cross-sectional area, measured in square centimeters (cm2). P = Actual pressure, measured in bars (bar) or kilopascals per square centimeter (kp/cm2).

Installation

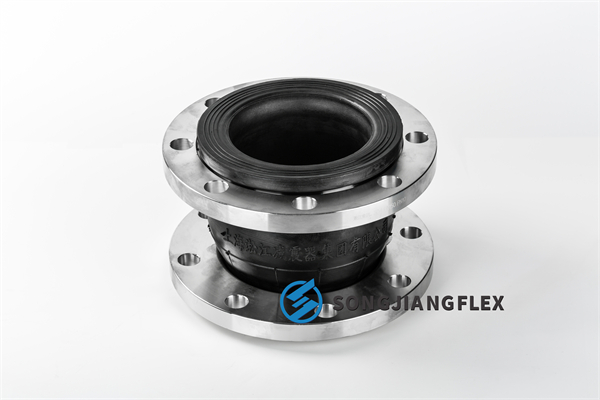

The turnable metal flanges make installation easier and eliminate twist.

The low inherent rigidity of Sungkiang expansion joints makes it easier to accommodate installation dimensions.

Check the permissible movements, temperature, pressure, and proper rubber quality before installation!

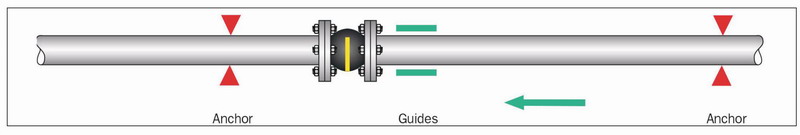

Compression rather than stretching. Torsion is not permitted.

Rubber joints should be easily checked regularly. I recommend that the rubber joint works in compression rather than stretching, and torsion is not allowed.

Maintenance instructions: observe whether the rubber joint is overstretched and keep the rubber joint at its normal length every month.

Pressure-restrained expansion joint on pump (with tie bar).

Absorb vibration, thus reducing noise in the engine room.

Lateral Rubber Expansion Joint Device

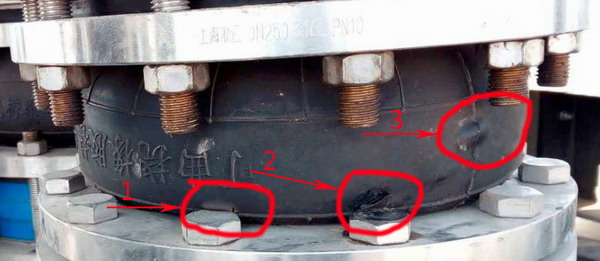

Installation: To ensure the expansion capability, according to the technical installation instructions, the assembly bolts should be installed with the bolt head facing away from the rubber pipe. (1) If it is not possible to install the bolts facing away from the rubber pipe, then it is necessary to ensure that the threaded bolts are as few as possible (not exceeding 2 millimeters or 3mm) to avoid damaging the body.

In the anchor rod pressure evenly distributed oblique sequence, progressive and lateral methods must be adopted.

The design of the expansion joints secures a sealing to the counter flange. That is why no sealing gasket is required.

Note: If the bolts and nuts are tightened too strongly, the sealing face might be crushed causing a function failure!

Counter flanges It is very important for the safe operating and life expectancy of the expansion joint to make a proper installation of the counter flanges (Fig. 2 to 5). The sealing face of the counter flange must be machined smooth and cover most of the rubber sealing face (or at least 80%) to ensure good sealing (Fig.2).

Precautionary measures:

- Do not paint or lubricate rubber parts of expansion joints!

- When welding work is to take place, the bellow has to be protected from welding heat and sparks!

-

Attention: Please strictly use the rubber fittings of the union according to the above requirements, if not use, cause any consequence, be not responsible for.

Related Link:“Galvanized” DN150 Single Ball Galvanized Flange Rubber Expansion Joint