The official website of Shanghai Songjiang Vibration Absorber Co., Ltd. presents: “Master’s Summary of Installation Precautions for Stainless Steel Bellows Compensators”. The purpose of designing bellows compensators is to allow the flexure of thin-walled bellows to absorb the displacement of specific pipelines. If installed improperly, the expansion life and pressure resistance of bellows compensators may decrease, leading to premature failure or damage to the pipeline.

Installation Precautions for Stainless Steel Bellows Compensators

The purpose of designing bellows compensators is to allow the flexure of thin-walled bellows to absorb the displacement of specific pipelines. If installed improperly, the expansion life and pressure resistance of bellows compensators may decrease, leading to premature failure or damage to the pipeline. Master summarizes the installation precautions for stainless steel bellows compensators.

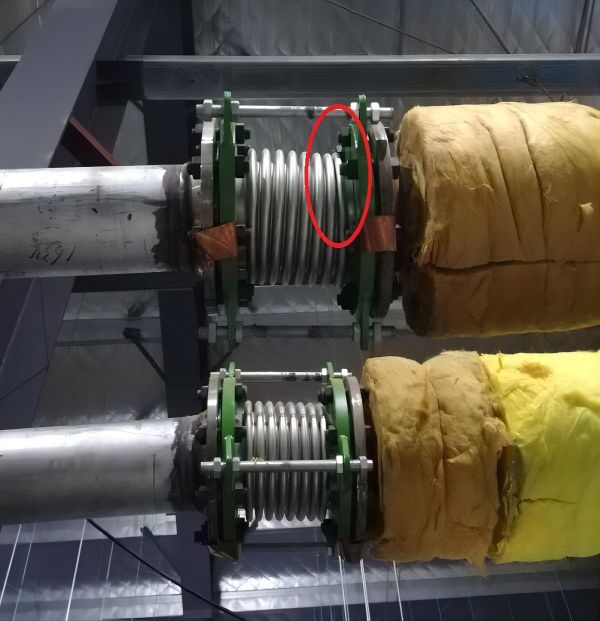

The flexure of the bellows absorbs the displacement of the pipeline, so the thickness of the bellows wall must not only be sufficient to withstand the design pressure but also thin enough to flex to a certain degree to absorb the expected displacement of the pipeline. After optimization, the wall thickness of the bellows will be smaller than that of other components in the same pipeline system. Installers must understand that bellows compensators are more fragile than other pipeline components, and various possible protective measures should be taken during installation. Shanghai Songjiang Group recommends avoiding surface dents, welding spatter, and situations where the bellows may be impacted during installation; using specific external wrapping methods to protect the bellows of the bellows compensator as much as possible, as the cost of cheap wrapping is much lower than the cost of replacing the bellows compensator due to carelessness; implementing correct and reasonable storage, handling, and installation will ensure that users have reliable bellows compensator products. Master summarizes the installation precautions for stainless steel bellows compensators.

The following recommendations are to prevent possible errors during installation; if there are any questions about the installation process, be sure to ask Shanghai Songjiang Group for answers before proceeding.

Must-do items:

- Check for damage during transportation, such as surface dents, fractures, or water stains on the carton;

- Store in a clean, dry environment and avoid exposure to busy traffic or harmful environments;

- If the product has lifting lugs for handling, be sure to use them during handling;

- Adjust the pipeline to match the bellows compensator, rather than stretching, compressing, or bending the bellows compensator to match the pipeline; these improper methods may cause the bellows compensator to exceed its preset load during operation;

- Try to keep one end of the flange loose until the bellows compensator is adjusted to the appropriate position before fixing it; if welding is used to connect the pipeline to the bellows compensator, remember to adjust the loose flange to the correct position first;

- If there are arrows marked on the product, install the bellows compensator according to the direction indicated by the arrow, which is the direction of the fluid flow;

- When installing bellows compensators with guide tubes, pay attention to the internal extension direction to be consistent with the direction of the fluid;

- After installation, before conducting a comprehensive pressure test, remember to remove all lifting devices;

- Check for any objects between the peaks of the bellows, and remove them immediately if found;

- One end of the bellows compensator must be fixedly supported.Prohibited Actions:

- Dropping or impacting the bellows compensator;

- Removing the transportation fixing rod before completing the installation;

- Removing the water-absorbing desiccant bags or external packaging before installation;

- Using flanges or transportation fixing rods as lifting lugs;

- Directly contacting the bellows compensator or its external wrapping with chains or any lifting devices;

- Special attention! The surface of the bellows should avoid contact with welding slag or arc during welding;

- Using cleaning agents containing chlorides;

- Using steel wire balls or brushes to clean the bellows;

- Applying pressure or twisting one end of the bellows compensator to align bolt holes, as the bellows generally cannot withstand torsion;

- Conducting hydrostatic tests or system purging before all sliding frames and fixed frames are installed;

- Using transportation fixing rods to withstand the thrust caused by fluid pressure during testing;

- Using pipeline hangers as sliding frames;

- Exceeding the rated test pressure provided by Shanghai Songjiang Group.

Warning: If improper installation methods or violations of prohibited actions are adopted, the warranty provided by Shanghai Songjiang Vibration Absorber Co., Ltd. will be void.