Shanghai Songjiang Vibration Absorber Co., Ltd.’s official website introduces the information on how to eliminate blind plate force when installing rubber expansion joints for water pumps. If the blind plate force cannot be eliminated, then choose anti-pull type rubber expansion joints to eliminate blind plate force and prevent damage to the rubber expansion joints.

Since the pump end is a fixed foundation and can be considered as a fixed end, the pipeline will not shift, and thus the axial thrust generated by the blind plate force will all be transferred to the main pipe at the water pump outlet, causing the main pipe to shift. When the displacement is too large, it may lead to the phenomenon of flexible rubber expansion joints being pulled out from the flange.

When the pump adopts straight-line piping (main pipe buried underground), as shown in the diagram of pump piping with straight-line piping (main pipe buried underground); the inlet and outlet pipes are the same; DN500 mm, and the supply water pressure is 0.55 MPa, which can explain this issue. When the pipe diameter is large or the water pressure is high, the blind plate force generated by the outlet pressure will be significant, causing a large thrust on the pump end and the buried outlet main pipe. Due to the resistance of the soil where the outlet main pipe is buried, the pipeline cannot shift. The thrust is all transferred to the pump, thus easily leading to damage to the pump foot bolts and pump foundation.

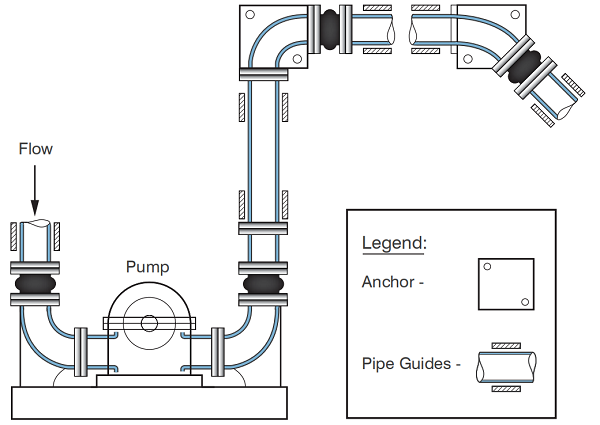

When the pump adopts vertical piping, the flexible rubber expansion joints installed on the pipeline will expand and push the pipeline upward under the action of the blind plate force generated by the water pressure. When the water pressure is too high, there is a possibility of the flexible rubber expansion joints being pulled out from the flange.

Analysis of blind plate force under different water pressures: Under different water pressures, the magnitude of the blind plate force generated at the blind end of the pump outlet pipe can be observed. It can be seen that with the increase of pipe diameter and water pressure, the blind plate force generated by the water flow also increases. Generally, when the pipe diameter is not less than 150 mm, if the pipeline is installed with flexible rubber expansion joints, it is advisable to set up anti-pull devices or fixed pipe racks to eliminate the blind plate force generated by the water pressure.

Countermeasures for blind plate force at the pump outlet piping: In the pump piping design, when the system needs to install flexible rubber expansion joints, the influence of whether the pipeline system can eliminate the blind plate force should be analyzed. If it cannot be eliminated, flexible rubber expansion joints with anti-pull should be selected or fixed pipe racks should be set up to eliminate the pipeline displacement caused by the blind plate force.