Shanghai Songjiang Vibration Absorber Group Co., Ltd. official website shares information on the directional instructions for bolts in WILLBRANDT flanged rubber expansion joints. We provide professional knowledge on various global brands in the field of flanged rubber expansion joints to assist users comprehensively.

The flange bolt connection must be tightened in the following manner:

Step One: Hand-tighten all bolts.

Step Two: Tighten all bolts in a cross pattern. Check for even spacing between flanges.

Step Three: Apply torque to bolts twice. Bolts should not be tightened all at once, as it may cause uneven stress and damage to the rubber sealing surface. Throughout the assembly process, ensure that the sealing surfaces are not inclined, and any protruding sealing surfaces should be evenly compressed on all sides. When installing silicone rubber expansion joints, the torque specified must be reduced by 30%. If leaks occur during subsequent pressure testing, bolts must be replaced and tightened in the correct sequence. If leaks persist in flange connections secured with bolts, the tightening torque must be slightly increased, and expansion joints must be reduced before re-tightening bolts. Throughout the assembly process, ensure that the expansion joints are not overly expanded or flattened.

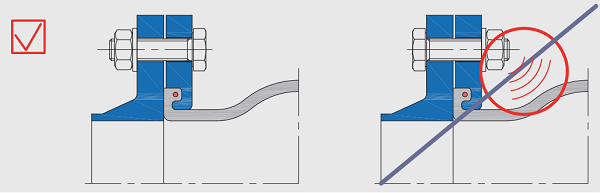

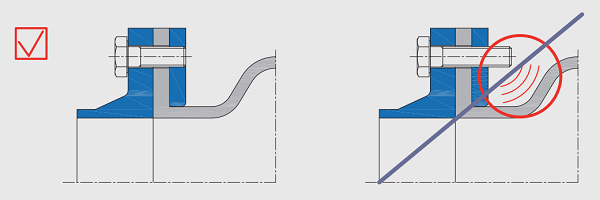

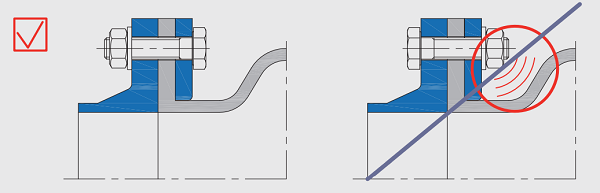

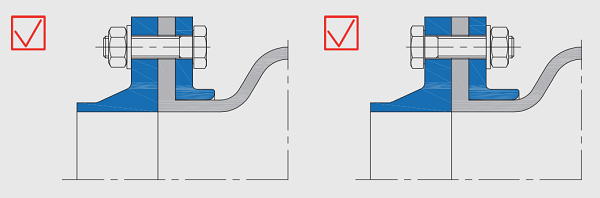

Summary: According to the installation direction instructions for flanged rubber expansion joints of the WILLBRANDT brand in Germany, we can observe in the schematic diagram that the direction of bolt installation is specified. If the nut direction is in line with the direction of the rubber expansion joint corrugations, flanges with bosses are required to prevent abrasion of the rubber corrugations by the bolts. If flanges with bosses are not used, then the nuts should be oriented towards the direction of the pipeline, effectively avoiding bolt abrasion of the rubber corrugations. What are the benefits of doing this? It can effectively protect the safe use of rubber expansion joints and increase their service life.