Shanghai Songjiang Vibration Absorber Group Co., Ltd. introduces information on EPDM (Ethylene Propylene Diene Monomer), offering rubber expansion joint products known for their high-temperature and acid resistance for various applications such as thermal pipelines, desulfurization systems, and spray pipelines. Here’s an overview of EPDM:

- Introduction:

- Chinese Name: 三元乙丙橡胶 (Sānyuán Yǐbǐng Xiàngjiāo)

- English Name: Ethylene Propylene Diene Monomer (EPDM)

- Constituents: Ethylene, propylene, and a small amount of non-conjugated diene hydrocarbons

- Characteristics: Excellent oxidation resistance, ozone resistance, and corrosion resistance

- Abbreviation: EPDM EPDM is a copolymer of ethylene, propylene, and a small amount of non-conjugated diene hydrocarbons. It is chemically stable with a main chain composed of saturated hydrocarbons and unsaturated double bonds only in the side chains. Due to its outstanding resistance to ozone, heat, and weathering, EPDM finds wide applications in automotive components, waterproofing materials for construction, wire and cable insulation, heat-resistant rubber hoses, tapes, automotive sealing components, among others.

- Introduction to EPDM Rubber Expansion Joints by Songjiang Group:

- Structure: All EPDM rubber expansion joints produced by Songjiang Group use EPDM rubber for both inner and outer layers.

- Content: The EPDM content inside the rubber expansion joints manufactured by our factory is approximately 50%, as verified by third-party content testing reports.

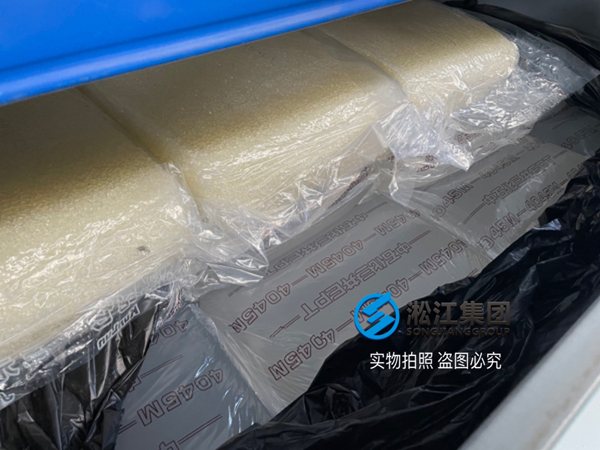

- Raw Material Selection: The EPDM rubber used in our factory’s EPDM rubber expansion joints is always sourced from Mitsui 4045 in Japan.

- High-Temperature Resistance: Suitable for temperatures up to 120°C, for applications such as boiler rooms, thermal pipelines, and ground-source heat pump systems (due to the 50% EPDM content, the heat resistance may not reach the highest level; the reliable maximum continuous working temperature does not exceed 120 degrees).

- Acid and Alkali Resistance: Suitable for weak acids and alkalis, such as lime slurry for desulfurization, seawater desalination, and spray applications in weak acid and alkali pipeline systems.

- Related Introduction to EPDM Original Rubber:

- Low Density and High Fillability: EPDM rubber has a low density of 0.87 and can be filled with a large amount of oil and fillers, reducing the cost of rubber products. It exhibits excellent aging resistance, ozone resistance, heat resistance, acid and alkali resistance, water vapor resistance, color stability, electrical properties, oil resistance, and flowability at room temperature.

- Corrosion Resistance: EPDM rubber exhibits good resistance to various chemicals such as alcohols, acids, alkalis, oxidants, refrigerants, detergents, animal and vegetable oils, ketones, and fats, although stability is lower in solvents such as hydrocarbons (e.g., gasoline, benzene) and mineral oils. Its performance deteriorates under prolonged exposure to concentrated acids.

- Water Vapor Resistance: EPDM rubber demonstrates excellent resistance to water vapor and is superior to other rubbers in terms of heat resistance. It maintains its appearance after nearly 100 hours of exposure to superheated steam at 230°C, while other rubbers such as fluororubber, silicone rubber, fluoro-silicone rubber, butyl rubber, nitrile rubber, and natural rubber show significant deterioration under similar conditions.

Resistance to Overheated Water: EPDM rubber exhibits good resistance to overheated water, depending on the sulfurization system used. EPDM rubber vulcanized with dithiodimorpholine (DTDM) or tetramethylthiuram disulfide (TMTD) shows minimal changes in mechanical properties after immersion in overheated water at 125°C for 15 months, with a volume expansion rate of only 0.3%.

-

- Electrical Properties: EPDM rubber offers excellent electrical insulation properties and corona resistance, comparable to or better than those of chlorosulfonated polyethylene, polyethylene, and cross-linked polyethylene. It boasts excellent insulation properties, with a volume resistivity of 10^16 Ω·cm, breakdown voltage of 30-40 MV/m, and dielectric constant (1kHz, 20°C) of 2.27.

- Elasticity: EPDM rubber has excellent elasticity due to its low cohesive energy density and flexible molecular chains, ranking second only to natural rubber and polybutadiene rubber, maintaining flexibility even at low temperatures.