ZB Type Non-Metallic Fabric Expansion Joint

The official website of Shanghai Songjiang Vibration Absorber Group Co., Ltd. introduces information about ZB Type Non-Metallic Fabric Expansion Joints. This product is mainly suitable for large fans, pipelines, and damping locations in steel plants, power plants, cement plants, chemical plants, etc. It exhibits excellent high-temperature resistance.

Material Composition:

The ZB-type non-metallic fabric fiber compensator is made from excellent performance materials such as silicone fabric (fluorine rubber fabric), polytetrafluoroethylene (PTFE), alkali-free glass fiber fabric, ultra-fine glass wool with good thermal insulation properties, and silica-alumina wool (ceramic fiber blanket for high temperatures), among others, through special manufacturing processes.

Product Features:

Large Compensation Range: The same compensator can meet the multi-dimensional compensation needs of the system.

No Thrust Reaction: Due to the flexibility of its own materials, it can unconditionally absorb the thermal expansion thrust of the previous section of the pipeline without transmitting it to the next section.

High Temperature Resistance, Corrosion Resistance: The materials used, such as silicone fabric (fluorine rubber fabric), glass fiber, polytetrafluoroethylene, etc., have excellent resistance to high temperatures and corrosion.

Noise Reduction and Vibration Isolation: Non-metallic materials like fiber fabric inherently have good sound absorption and vibration isolation properties, effectively reducing noise and vibration generated by equipment such as boilers and fans.

Technical Requirements:

1.The non-metallic fabric fiber compensator should operate safely for an extended period, with a service life of no less than 6 years (7500 operating hours per year).

2.The normal temperature allowable fatigue life of the non-metallic fabric fiber compensator should be no less than 1000 times (safety factor for fatigue life should be no less than 15).

3.The non-metallic fabric fiber compensator should be able to absorb axial and lateral displacements of all connected equipment and smoke ducts under all operating and accident conditions.

4.All non-metallic fabric fiber compensators should be designed to be damage-free, leak-free, capable of withstanding various high-temperature offset ranges, with built-in stainless steel wire mesh, and able to withstand the maximum design positive and negative pressure plus a margin of 1.25 times.

5.Materials of non-metallic fabric fiber compensators for smoke ducts should meet the requirements for withstanding high temperatures of smoke and air, and resistance to corrosion and wear from smoke. The sealing between non-metallic fabric fiber compensators and smoke ducts should be 100% airtight. For the insulation inside non-metallic fabric compensators on smoke ducts, the characteristics of the smoke should be considered.

6.Non-metallic fabric fiber compensators on smoke ducts and air ducts are arranged outdoors; their materials should meet various original design conditions provided in this attachment. Special attention should be paid to their ability to withstand low temperatures outdoors in winter.

7.The outer surface temperature of the skin of non-metallic fabric fiber compensators should not exceed 70°C.

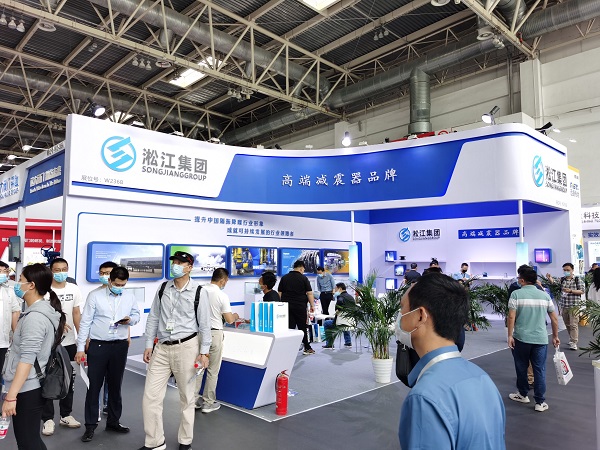

Factory Photos of ZB Type Non-Metallic Fabric Fiber Compensator:

Related Link:KFT Type High-Temperature Duct Rubber Expansion Joint