RE Type Desulfurization Rubber Expansion Joint

Welcome to the official website of Shanghai Songjiang Vibration Absorber Co.,Ltd. Our Rubber Joints section covers various fields, providing information about RE Type Desulfurization Rubber Expansion Joints. This product is primarily used at the inlet and outlet of slurry circulation pumps in power plants, serving to absorb shocks and reduce noise.

1.Photographs of the Physical Product of RE Type Desulfurization Rubber Expansion Joints:

2. Introduction to the Parameters of RE Type Desulfurization Rubber Expansion Joints:

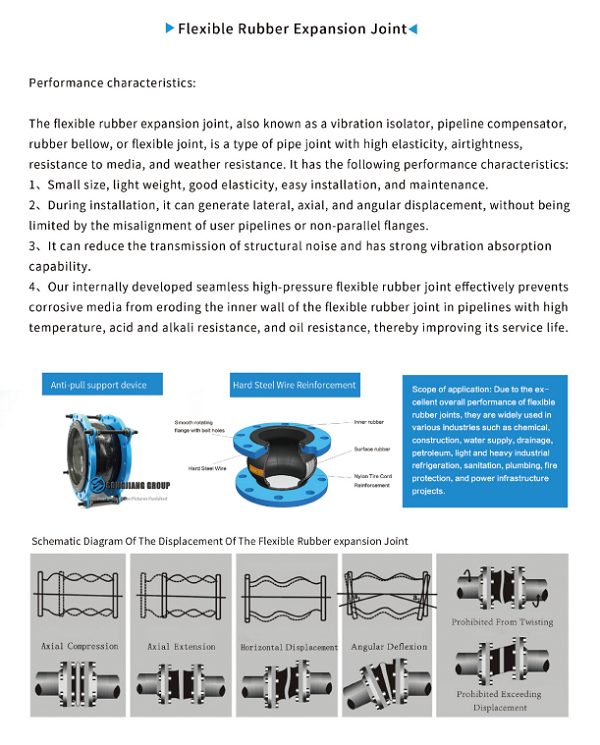

3.Introduction to RE Type Desulfurization Rubber Expansion Joints:

4.Introduction to the Raw Materials of the Intermediate Rubber Section in RE Type Desulfurization Rubber Expansion Joints:

5.On-site Shipment of RE Type Desulfurization Rubber Expansion Joints:

6.On-site Installation of RE Type Desulfurization Rubber Expansion Joints:

7.The Introduction of Flue Gas Desulfurization Processes in Power Plants:

The flue gas desulfurization process in power plants can be categorized into three main types based on the desulfurizing agent and the state of the desulfurization reaction: wet, dry, and semi-dry methods.

Wet Desulfurization Process:

Wet desulfurization processes around the world share similar procedures, forms, and mechanisms, primarily involving the use of alkaline solutions as desulfurizing agents to absorb SO2 from flue gas.

Common wet desulfurization methods include limestone/lime-gypsum method, seawater method, dual-alkali method, sodium sulfite circulation method, and magnesia oxidation method.

Dry Desulfurization Process:

Dry desulfurization processes for power plant flue gas began in the early 1980s.

Main dry desulfurization methods include electrostatically charged dry sorbent injection desulfurization, electron beam irradiation method, adsorption method, etc.

Semi-Dry Desulfurization Process:

The semi-dry desulfurization process integrates the advantages of both wet and dry desulfurization methods, offering broad application prospects.

Prominent semi-dry desulfurization methods include spray drying method, circulating fluidized bed method, humidification ash circulation method, and flue gas injection method.

Flue gas desulfurization technology is predominantly led by wet desulfurization processes, while dry and semi-dry methods are also under development.

8. Introduction to the Factory of RE Type Desulfurization Rubber Expansion Joints:

Related Links: Thermal Power Rubber Expansion Joint Cases