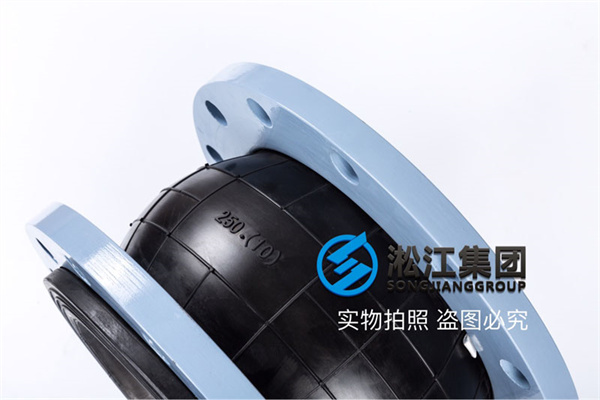

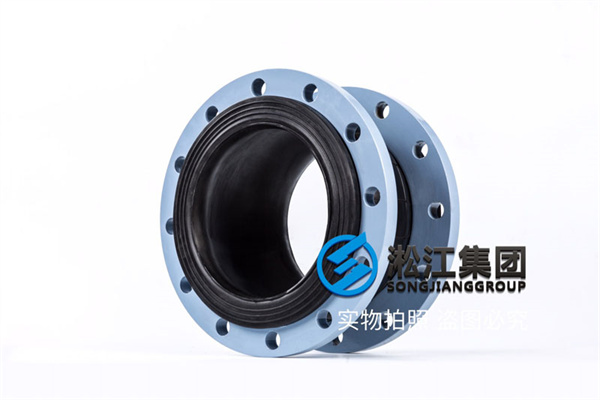

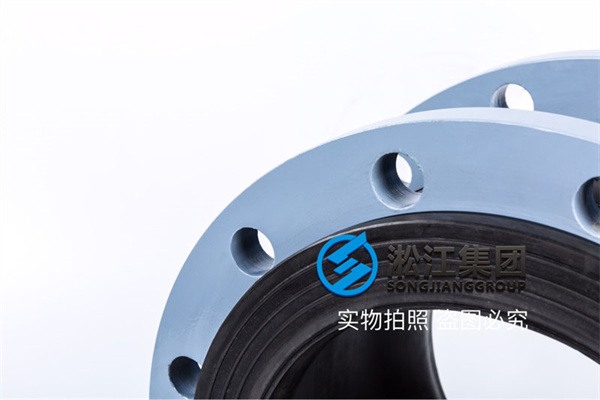

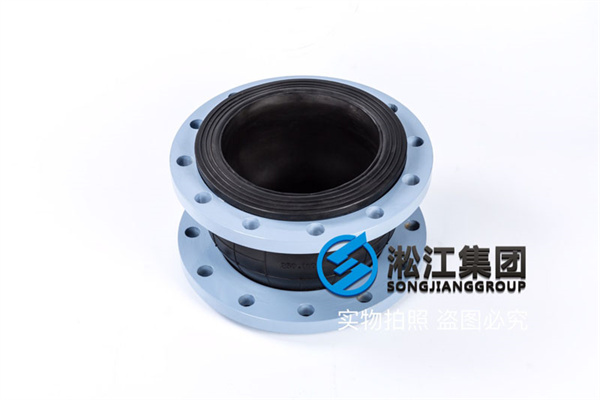

【OEM】DN250 Single Sphere Rubber Expansion Joint OEM Factory “3-Year Warranty”

Shanghai Songjiang Vibration Absorber Co.,Ltd. official website introduces: “【OEM】DN250 Single Sphere Rubber Expansion Joint OEM Factory” with “3-Year Warranty” information. Songjiang Group has its own research, production, and testing capabilities, allowing customers to purchase with confidence and use with peace of mind, which is our principle.

OEM Labeling Instructions:

Our factory has a set of non-standard molds, providing OEM labeling services for valve manufacturers. The main models include: DN40~DN400, pressure 1.6Mpa, minimum order quantity: 100 units or more. Generally, we have stock for common water applications. If special materials are required, such as non-standard EPDM rubber, customization is needed. The minimum order quantity for each model is 100 units or more, with a lead time of 30 days.