【NG】K16S-63 Rubber Hose Joint for Injection Molding Machine

Shanghai Songjiang Vibration Absorber Co.,Ltd. official website introduces the information of 【NG】K16S-63 rubber pipe joint for SDKSS63 injection molding machine. The NG type rubber pipe joint product is used for the return oil pipeline of imported injection molding machine hydraulic system. Below is the introduction of K16S-63 rubber pipe joint.

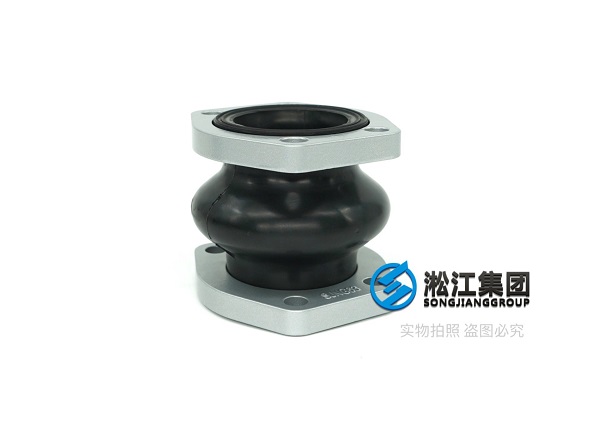

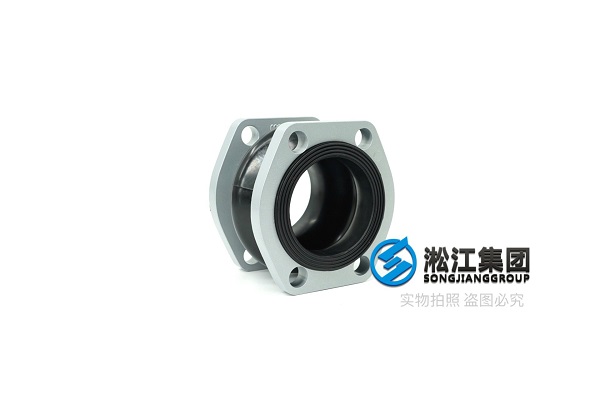

1. Physical photo of K16S-63 rubber pipe joint for injection molding machine:

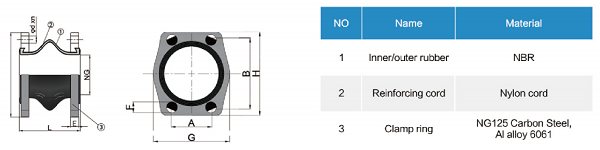

2. Technical parameters of K16S-63 rubber pipe joint for injection molding machine:

Rubber Material: Nitrile Rubber

Flange Material: Aluminum Alloy (NG125 is Carbon Steel) with Powder Coating.

Installation Position: Return Oil Pipeline of Injection Molding Machine Hydraulic System.

Function: Provides vibration damping and noise reduction.

Warranty: 12 months.

Delivery Time: Available in stock.

3.Injection Molding Machine Introduction:

An injection molding machine, also known as an injection molding machine or injection machine, is the primary molding equipment used to produce various shapes of plastic products using thermoplastic or thermosetting plastics and plastic molds. It can be classified into vertical, horizontal, and all-electric types. The injection molding machine heats the plastic, applies high pressure to the molten plastic, and injects it into the mold cavity to fill it completely.

The injection system is one of the main components of the injection molding machine and generally comes in three main forms: plunger, screw, and screw pre-plasticizing plunger injection. The screw type is the most widely used. Its function is to heat and melt a certain amount of plastic within a specified time in each cycle of the injection molding machine and inject the molten plastic into the mold cavity through the screw under a certain pressure and speed. After injection, the molten material injected into the mold cavity is allowed to solidify.

The hydraulic transmission system provides power for various actions required by the injection molding machine during the process and meets the requirements of pressure, speed, temperature, etc., for various parts of the injection molding machine. It mainly consists of various hydraulic components and hydraulic auxiliary components, with the oil pump and motor being the power source. Various valves control the hydraulic pressure and flow to meet the requirements of the injection molding process.

4.K16S-63 Injection Molding Machine Rubber Avoidance Pipe Joint Delivery Site:

5.The factory introduction of the K16S-63 injection molding machine rubber avoidance pipe joint:

Related link: Petroleum and Petrochemical Rubber Joint Cases