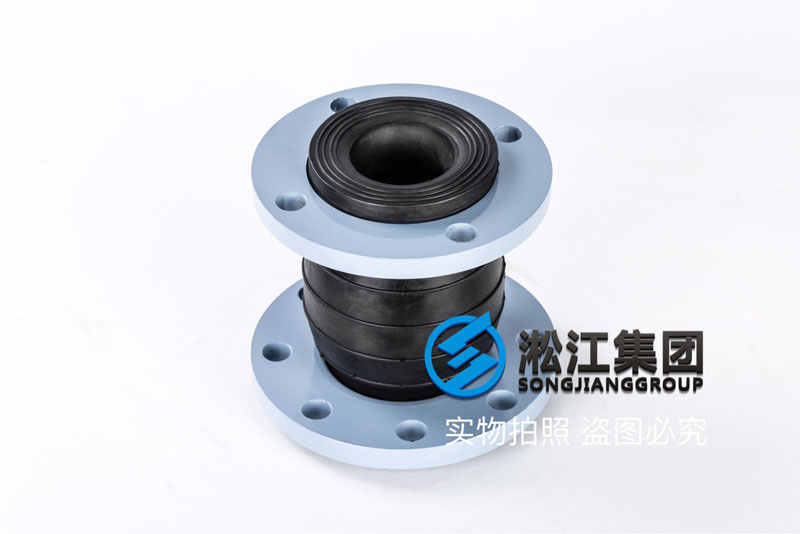

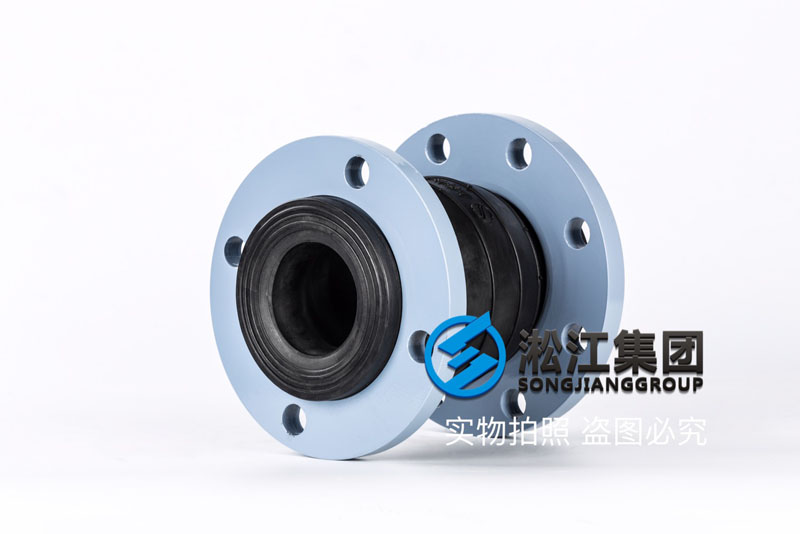

DN80x65 Eccentric Rubber Flexible Joint for ‘No Negative Pressure Water Supply’

The official website of Shanghai Songjiang Shock Absorber Group Limited introduces: “DN80x65 Eccentric Rubber Flexible Joint for ‘No Negative Pressure Water Supply.’ ” Songjiang Group provides rubber flexible joint products for numerous high-end water supply equipment manufacturers, offering excellent vibration reduction and noise reduction effects.

Flange Material: QT450 or Stainless Steel 304

Rubber Material for No Negative Pressure Water Supply Equipment: Natural Rubber (for ordinary water, non-corrosive, up to 80 degrees Celsius).

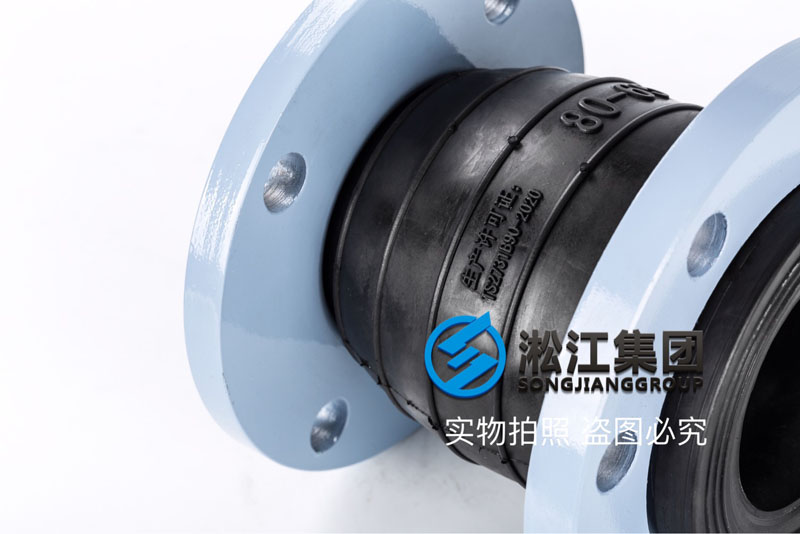

Production Technology: Our factory is certified by TUV Rheinland in Germany, and our products have been inspected and approved by the Shanghai Municipal Quality and Technical Supervision Bureau. We have our own research and development team, design department, and production facility. Each rubber joint product is engraved with our factory name (to ensure we can provide after-sales service for customers even after several years), rather than just attaching a label. This is because we have over 500 sets of our own molds, making us incomparable to small manufacturers.

Introduction to No Negative Pressure Water Supply: No negative pressure water supply equipment uses the municipal pipeline network as its water source and fully utilizes the existing pressure of the municipal pipeline network to create a closed and continuous pressure-boosting water supply system. It is energy-efficient, minimizes secondary water quality pollution, and is an extension of variable frequency constant pressure water supply equipment.

No Negative Pressure Water Supply Equipment: Typically, when we talk about no negative pressure water supply equipment, we are referring to variable frequency no negative pressure water supply equipment, which is directly connected to the water supply pipeline network. Traditional water supply methods rely on water tanks, where the water in the tank is generally supplied by the municipal water pipe, and this results in pressurized water becoming zero when it enters the tank, leading to a significant waste of energy.

In contrast, no negative pressure water supply equipment is an ideal energy-saving water supply system that can be directly connected to the municipal water supply pipeline network without causing any adverse effects on the network. It directly increases the pressure on top of the existing municipal network pressure, saving energy. It is also fully enclosed, pollution-free, space-efficient, quick to install, reliable in operation, and easy to maintain.

No negative pressure water supply equipment achieves this by using intelligent control technology and pressure stabilization compensation technology to ensure that the equipment does not create negative pressure in the municipal pipeline network, ensuring uninterrupted water supply to the user network. The flow controller used in the equipment can automatically adjust the input water volume from the municipal pipeline network while maintaining the minimum service pressure, ensuring that the municipal network does not experience negative pressure. During peak water usage, the energy storage container releases a certain pressure of nitrogen gas to compensate for any insufficient water supply from the municipal pipeline network. The two-way compensator stores energy during periods of low water usage and provides pressure stabilization compensation to the user pipeline during the night and low-flow water supply, preventing frequent pump starts. It makes full use of the pressure in the municipal pipeline network, resulting in significant energy savings.

To connect water pumps to the municipal water supply network while complying with regulations and preventing negative effects on other users’ water supply, a no negative pressure flow controller, a divided chamber pressure stabilization compensation tank, a two-way compensator, and other components are required between the pump inlet and the municipal pipeline network. The no negative pressure flow controller continuously monitors the municipal pipeline network pressure, ensuring that the network does not experience negative pressure while fully utilizing the existing pressure in the municipal pipeline network.