DN50 Hydraulic Oil Rubber Expansion joint “It’s the hard truth if it lasts for 3 years”

Shanghai Songjiang Vibration Absorber Group Co., Ltd.’s official website introduces the information of the DN50 Hydraulic Oil Rubber Expansion joint. We provide oil-resistant rubber Expansion joint products for hydraulic oil pipelines, using nitrile rubber N41 in production, with a rubber content of approximately 50%. These products are primarily designed to withstand hydraulic oil, such as No. 45 anti-wear hydraulic oil.

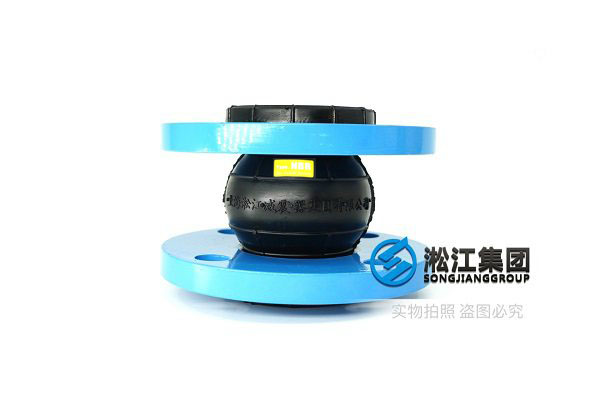

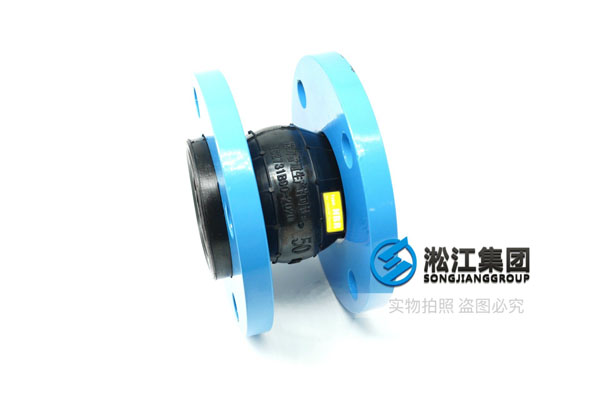

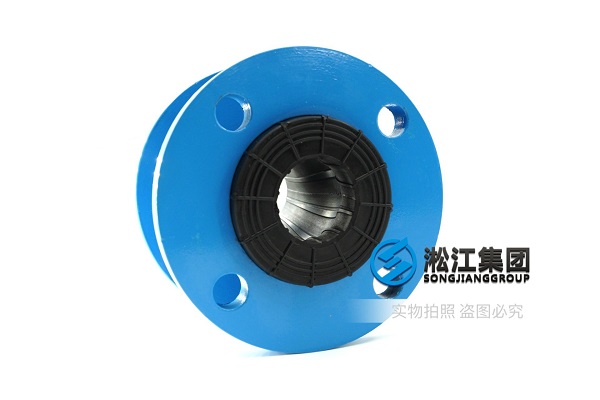

1.Physical Photos of DN50 Hydraulic Oil Rubber Expansion joint:

2.Hydraulic Oil Rubber Expansion joint Introduction:

Qualification Certificate: Qualification Certificate, Quality Guarantee, Inspection Report, TS Pressure Pipeline Production License of Rubber Expansion Joint Industry, National Type Test Report, Third Party Performance Test Report, Content Component Test Report.

3.Hydraulic Oil Introduction: Hydraulic oil is a hydraulic medium that utilizes the energy of hydraulic pressure in hydraulic systems.

It plays a role in energy transmission, anti-wear, system lubrication, corrosion resistance, rust prevention, and cooling in hydraulic systems. For hydraulic oil, the first requirement is to meet the viscosity of the liquid under working and startup temperatures. Since the viscosity of hydraulic oil directly affects hydraulic actions, transmission efficiency, and precision, it is also required that the oil’s viscosity-temperature performance and shear stability meet various requirements for different purposes. Hydraulic oil comes in various types, and there are different methods of classification. For a long time, it has been classified based on usage, as well as based on oil types, chemical composition, or flammability. These classification methods only reflect the nature of the oil but lack systematicity and make it difficult to understand the relationships and development among different types of oils. Anti-wear hydraulic oil (HM hydraulic oil) has evolved from the base of anti-rust and anti-oxidant hydraulic oil. It includes high-zinc alkaline, low-zinc alkaline, neutral high-zinc, and ashless series products. They are divided into four grades based on their kinematic viscosity at 40°C: 22, 32, 46, and 68.

Applications:

(1) Anti-wear hydraulic oil is mainly used in the hydraulic systems of heavy-duty, medium-pressure, and high-pressure vane pumps, piston pumps, and gear pumps, such as YB-D25 vane pumps, PF15 piston pumps, CBN-E306 gear pumps, and YB-E80/40 double pumps.

(2) It is used in the hydraulic systems of medium-pressure and high-pressure engineering machinery, imported equipment, and vehicles. This includes hydraulic systems for computer numerical control machine tools, tunnel boring machines, crawler cranes, hydraulic excavators, and coal mining machines.

(3) In addition to applications in various hydraulic pumps’ mid-to-high-pressure hydraulic systems, it can also be used for the lubrication of industrial gears (except worm gears and hyperbolic gears) under medium loads. The product is suitable for an operating environment temperature of -10°C to 40°C. It exhibits good adaptability to nitrile rubber.

4.Hydraulic Oil Rubber Expansion Joint Shipping Site:

5.Hydraulic Oil Rubber Expansion Joint Factory Introduction: