DN150 Cutting Fluid Centralized Treatment System Rubber Flexible Joint

The official website of Shanghai Songjiang Vibration Absorber Group Co., Ltd. introduces information about DN150 Cutting Fluid Centralized Treatment System Rubber Flexible Joint. Songjiang Group provides high-quality rubber flexible joints for the emulsion circulation pumps of numerous automotive engine manufacturing plants, primarily designed for emulsion pipelines. These joints exhibit excellent oil resistance, wear resistance, and high-temperature resistance. They are primarily made using Chinese petroleum-based Nitrile Rubber N41, with a rubber content of about 50%. Below is a detailed introduction.

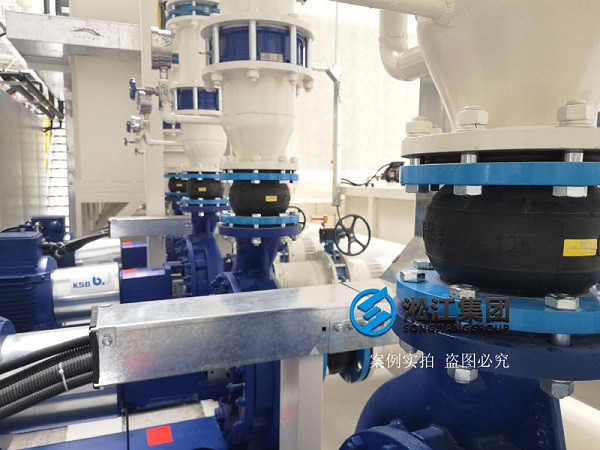

1. Physical Photos of Cutting Fluid Centralized Treatment System Rubber Flexible Joint:

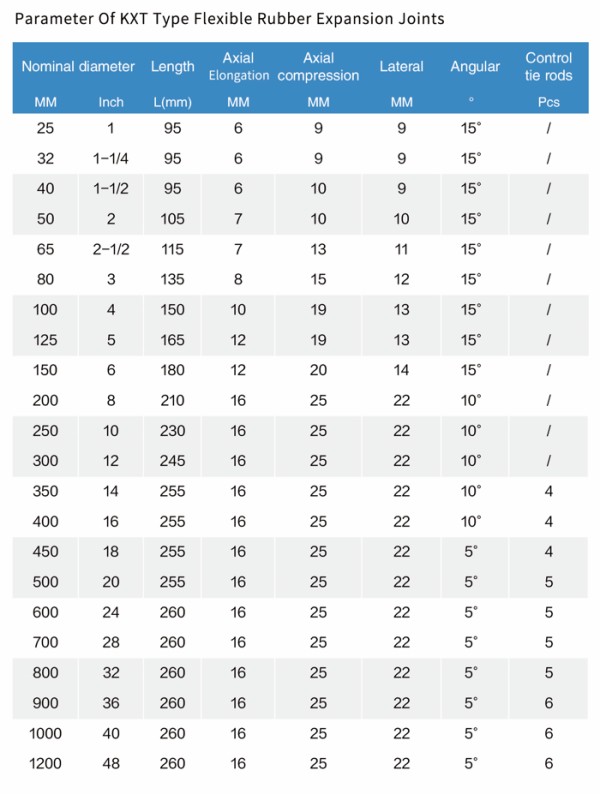

2. Introduction of Cutting Fluid Centralized Treatment System Rubber Flexible Joint:

Qualification Certificate: Qualification Certificate, Quality Guarantee, Inspection Report, TS Pressure Pipeline Production License of Rubber Expansion Joint Industry, National Type Test Report, Third Party Performance Test Report, Content Component Test Report.

3.On-Site Presentation of Rubber Flexible Joints for Cutting Fluid Centralized Treatment Systems at Geely Yiwu Engine Factory:

4. Introduction to Cutting Fluid Centralized Treatment Systems:

As environmental and energy conservation requirements in China continue to rise, the process requirements for metal cutting fluid treatment in manufacturing factories are also constantly increasing. To protect the workshop environment, cutting fluid treatment equipment has transitioned from being individually configured for each machine tool to centralized filtration and treatment. Cutting fluid centralized filtration systems are known for their high efficiency, system stability, reduced cutting fluid replacement frequency, decreased workload for personnel, and extended lifespan of processing center equipment, among other benefits.

Cutting fluid centralized treatment systems collect and process the cutting fluid used by all machine tools in the workshop through a pipeline connection to a centralized filtration system. The system consists of different modules and can be customized according to the customer’s specific needs. This consumable-free cutting fluid centralized treatment system extends the usage time and quality of cutting fluid, enhances the automation level of factory production management, reduces hazardous waste generation, and minimizes emissions.

Scope of centralized purification projects: Metal processing fluid centralized filtration and purification equipment, vacuum paper belt filtration machine, vacuum pre-coating centralized filtration system, centrifugal solid-liquid two-phase separation, and centrifugal solid-liquid-liquid three-phase separation, among others.

Cutting fluid centralized treatment systems are mainly used in industries such as:

Automotive Industry: Engine cylinder head and block lines, gearboxes, crankshafts, connecting rods.

Bearing Industry: Bearing grinding and super-finishing, as well as cleaning.

Metallurgy Industry: Rolling mill process lubrication, rolling mill bearing process lubrication.

Machine Tool Industry and other wet processing industries.

Our company’s products have been used in numerous domestic machine tool factories, bearing factories, steel mills, and automotive component factories.

5. On-Site Delivery of Cutting Fluid Centralized Treatment System Rubber Flexible Joints:

6.Introduction to the Factory of Rubber Flexible Joints for Cutting Fluid Centralized Treatment Systems: