DN100 Lined PTFE Rubber Expansion Joint (S304+NR)

Shanghai Songjiang Vibration Absorber Group Co., Ltd. official website introduces information about the ‘2DN100 Lined PTFE Rubber Expansion Joint (S304+NR).’ Songjiang Group provides high-quality PTFE rubber expansion joints for various chemical pipelines. Here is a detailed introduction of the DN100 Lined PTFE Rubber Expansion Joint. It features flanges made of stainless steel S304material, natural rubber for the rubber component, and an inner lining of polytetrafluoroethylene (PTFE) material. This design offers resistance to strong acids and alkalis and is suitable for sulfuric acid pipelines. However, it has two limitations: it cannot withstand temperatures exceeding 60 degrees Celsius and is not suitable for negative pressure applications.

1.DN100 Lined PTFE Rubber Joint (S304+NR) – Real-life Photos:

2.DN100 Lined PTFE Rubber Expansion Joint (S304+NR) Introduction:

- Flange Material: Stainless Steel Flange (available in 304 and 316 options)

- Rubber Material: Natural Rubber; also available in Fluororubber, Nitrile Rubber, and Ethylene-Propylene-Diene Monomer (EPDM) Rubber (We use Japanese Mitsui 4045 EPDM Rubber, 100% virgin rubber with no recycled materials, backed by a tenfold compensation guarantee)

- Lining Material: Polytetrafluoroethylene (PTFE) Lining (Using South Korean Daikin PTFE)

- Lead Time: No stock available, production takes approximately 7 days

- Warranty: 1-year quality guarantee”

Please let me know if you need any further information.

Note: Different materials are suitable for different media environments. The following is the product performance of Shanghai Songjiang Group, and it may not apply to products from other manufacturers. Due to variations in material brands, formulations, content, and processes used by different manufacturers, product results can vary significantly. For example, with the same rubber material, our factory has a rubber content of 50%, with no recycled components, and all raw materials have brand names. Our production process is also strictly controlled, ensuring that our products can be used in the following environments with a 100% quality guarantee:

NR (Natural Rubber): Suitable for temperatures up to 80 degrees Celsius, and for common water, domestic sewage, HVAC circulating water, river water, cooling water, fire water, drinking water, air, and compressed air. NBR (Nitrile Rubber): Suitable for hydraulic oil, emulsions, lubricating oil, light oil, and petroleum extraction applications. NBR-TS (Nitrile Rubber for Gasoline and Diesel): Suitable for gasoline, diesel, and aviation kerosene. EPDM (Ethylene Propylene Diene Monomer): Suitable for temperatures up to 120 degrees Celsius, and for hot water, weak acids, strong alkalis, seawater, food, beverages, natural gas, power plant lime slurry, power plant desulfurization, limestone, solar hot water, ground source heat pumps, lithium battery acid-alkali pipelines, automotive painting, automotive electrophoresis, wastewater, leachate. PTFE Lining: Suitable for temperatures below 80 degrees Celsius, strong acids, strong alkalis, aviation kerosene, petroleum, diesel, gasoline (not suitable for negative pressure vacuum applications). FKM (Fluoroelastomer): Known for resistance to acids, alkalis, oils, high temperatures, and has high versatility but comes at a higher price.

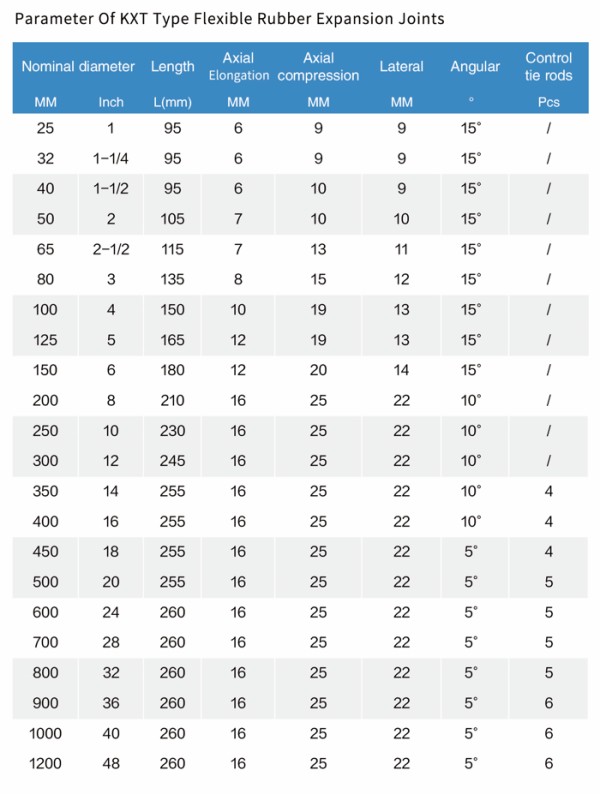

3.Parameter Introduction of DN100 Lined PTFE Rubber Expansion Joint (S304+NR):

4.Material Introduction for DN100 Lined PTFE Rubber Expansion Joint (S304+NR):

5.Factory Introduction for DN100 Lined PTFE Rubber Expansion Joint (S304+NR)

Related link: You can also use stainless steel metal hose products for pipelines with high acidity and alkalinity: JTW-PTFE Type PTFE-lined Teflon Metal Hose

![[Shanxi Kangwei Hongtai Coal Washing Plant] Rubber Expansion Joint Contract](https://www.sungkiangflex.com/wp-content/themes/sj-1/timthumb.php?src=https://www.sungkiangflex.com/wp-content/uploads/2024/06/Shanxi-Kangwei-Hongtai-Coal-Washing-Plant-Rubber-Expansion-Joint-Contract-1.jpg&h=300&w=400&zc=1)