“Wuhan Metro Line 6 Refrigeration Station” Damping Spring Vibration Isolator

1. Introduction to Wuhan Metro Line 6 Refrigeration Station Project:

Wuhan Metro Line 6, the fifth completed and operational subway line in Wuhan City, Hubei Province, China, commenced operations on December 28, 2016, with the first phase (from Jinyinhu Park Station to Dongfeng Corporation Station). Its distinctive color is parrot green.

Wuhan Metro Line 6 follows a semi-circular route, starting from Xincheng 11th Road Station in Dongxihu District in the northwest, passing through Jiang’an District, Jianghan District, Qiaokou District, and Hanyang District, and ending at Dongfeng Corporation Station in Caidian District in the southwest. Crossing the Han River, the line connects areas such as Wuhan Sports Center, Wuhan International Expo Center, Hanyang Commercial Center, Hankou Commercial Center, Zhanbei Residential Cluster, Changqing Garden, and Jinyinhu. It serves as a major channel for passenger flow between Hanyang and Hankou.

As of December 2021, Wuhan Metro Line 6 has a total length of 42.95 kilometers, all of which are underground. It comprises 32 stations, all of which are underground, and operates with 6-car Type A trains.

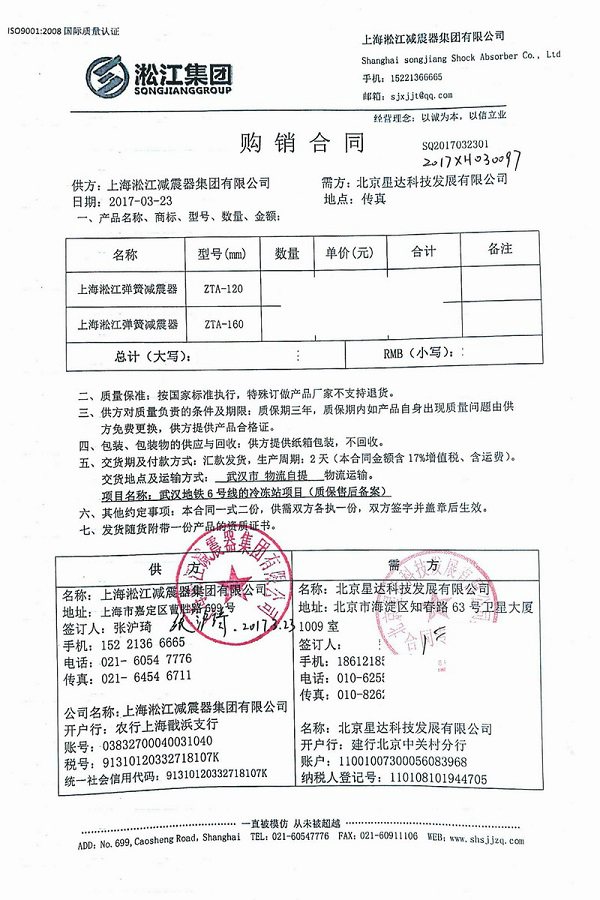

2.The contract for spring shock absorbers at the Wuhan Metro Line 6 refrigeration station:

3.The on-site factory inspection of spring vibration isolator at the Wuhan Metro Line 6 refrigeration station:

Every damping spring vibration isolator must meet the factory requirements before being delivered.

4.Product Introduction of Spring Vibration isolator for Wuhan Metro Line 6 Refrigeration Station:

The damping spring vibration isolator (patented product) combines the advantages of low frequency and high damping of steel spring shock absorbers, eliminating the inherent resonance amplitude phenomenon of steel springs.

Product Features:

(1)The outer shell is made of high-quality steel material, ensuring that the shock absorber will never break during transportation and operation, thus extending its service life.

(2)Wide load range for user selection, low natural frequency for good vibration isolation effect. The compact structure and small size facilitate easy installation and replacement, ensuring safety, reliability, and long service life.

(3)Strong adaptability to working environments, capable of normal operation in environments ranging from -40°C to 110°C. It shows significant effects in isolating active vibration, passive vibration, impact vibration, and solid-borne noise. It is an ideal shock absorber for vibration isolation, noise reduction, environmental protection, and vibration pollution control.

The shock absorber has three installation forms. The upper and lower surfaces of the damping spring shock absorber are equipped with non-slip rubber pads. For power equipment with minor disturbances, the shock absorber can be placed directly under the equipment’s base without fixation. For equipment with greater disturbances, it can be fixed by mounting holes on the upper surface, and the bottom mounting holes of the shock absorber can be fixed to the ground (or bracket).