The contract for metal hose in the Lihua Beneficial Oil and Gas Recovery Project

The official website of Shanghai Songjiang Vibration Absorber Group Co., Ltd. introduces the contract information for metal hoses in the Lihua Beneficial Oil and Gas Recovery Project. Our factory produces products such as stainless steel wire braided metal hoses and PTFE rubber joints. The following is an introduction to the contract for rubber joints supporting the oil and gas recovery project.

1. Introduction to Oil and Gas Recovery:

Oil and gas recovery at gas stations refers to the collection of volatile gasoline vapors during the processes of loading and unloading gasoline and refueling vehicles. This is achieved through methods such as absorption, adsorption, or condensation. The goal is to either reduce the pollution caused by oil and gas or transform the gas into liquid, making it reusable as gasoline. Oil depot gas recovery involves the collection of vapor emissions from volatile oil and gas at the oil depot and loading arms through the main pipeline. Similar to gas stations, the collected gas is treated through absorption, adsorption, or condensation methods to reduce pollution or transform it back into gasoline for reuse.

Oil and gas recovery is an energy-saving and environmentally friendly technology. It involves the recovery of oil vapors emitted during the transportation, storage, and loading/unloading processes to prevent atmospheric pollution and eliminate safety hazards. By improving energy utilization and reducing economic losses, significant benefits can be achieved. Common methods include adsorption, absorption, condensation, and membrane separation systems. The oil tanker’s gas recovery system ensures a fully enclosed gas recovery during the loading and unloading processes, limiting the emission of oil and gas into the atmosphere. The system connects the tanker’s oil delivery pipe and gas recovery pipe into a closed gas recovery pipeline. While unloading, the gas from the gas station tank is recovered through the return gas pipeline to the tanker, which then transports the gas back to the oil depot for processing, achieving the purpose of gas recovery.

The oil input process may increase the volatility and evaporation of oil and gas due to fluctuations in the liquid level. Therefore, the oil injection pipe must be submerged below the liquid surface to minimize liquid disturbance. The opening of the gas recovery pipe is equipped with special opening function devices. When the gas recovery pipeline of the tanker is correctly connected to the oil tank, the recovery port will open, and the exhaust pipe will close, allowing the gas in the tank to be completely returned to the tanker.

The oil and gas recovery system consists of three parts: quick couplings and caps at the bottom of the tank, manual or pneumatic valves, elbows, seamless steel pipes; seamless steel pipes passing through the bottom and top of the tank or external pipe connection systems; elbows, manual or pneumatic valves, rubber hoses, parallel main pipes, and elbows returning into the tank at the top.

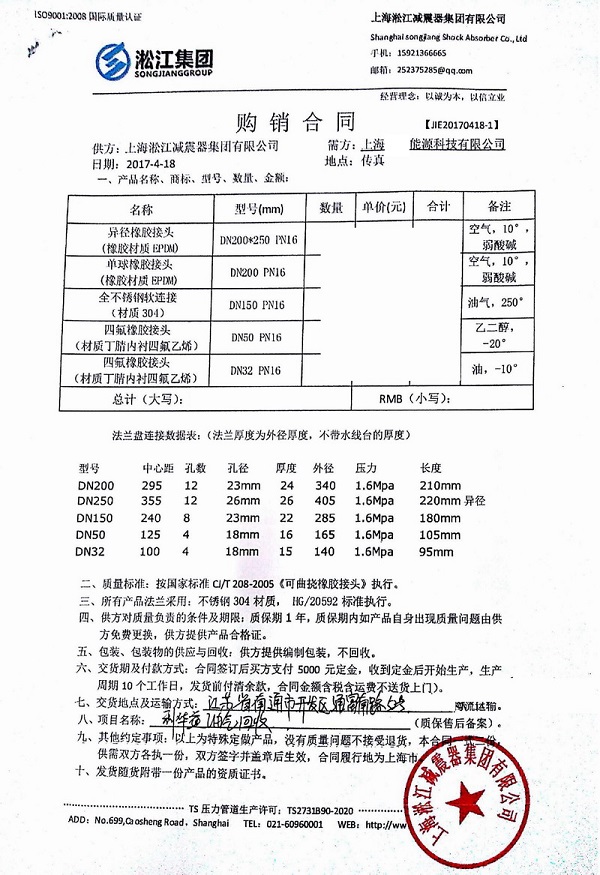

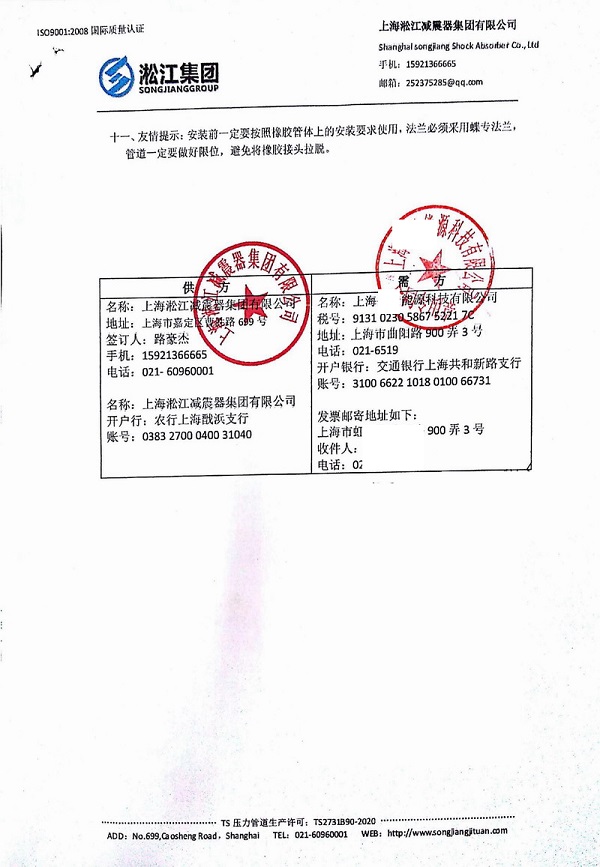

2. Introduction to the Metal Hose Contract for the Lihua Beneficial Oil and Gas Recovery Project:

Below is the scanned copy of the contract. The following is a genuine scanned copy of the contract; please do not modify or reproduce. Thank you for your cooperation.

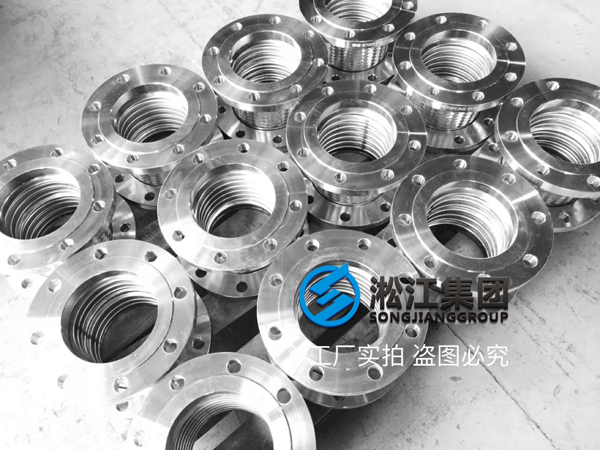

3. Introduction to the Metal Hose for the Lihua Beneficial Oil and Gas Recovery Project:

The customer’s requirements are quite high, strictly adhering to the HG/20592 standard for production. All flanges are produced using stainless steel 304 material. The stainless steel 304 raw materials used in our factory are subjected to nickel content testing using a spectrometer before entering the factory, ensuring customer confidence in usage.

Different media require the selection of different materials to avoid potential quality issues. It is crucial not to compromise material selection for the sake of price, as such a decision could lead to substantial losses.

Disclaimer: Our factory does not have any branches nationwide, strictly preventing counterfeiting! Phone: 15921366665 (same number for WeChat)

Related link:【304】DN150 Stainless Steel Flange Potable Water Grade Rubber Expansion Joint