“Shanghai Natural Gas Trans-River Tunnel” Oil-resistant Rubber Expansion Joint Contract

Shanghai Songjiang Vibration Absorber Co.,Ltd. Official Website introduces: 【Shanghai Natural Gas Trans-River Tunnel】Oil-resistant Rubber Expansion Joint Contract Information. Songjiang Group provides high-quality oil-resistant rubber expansion joints for numerous natural gas trans-river tunnels. Below is a detailed introduction.

1.Shanghai Natural Gas Cross-River Tunnel Information Introduction:

The project of the Shanghai Natural Gas Main Pipeline Network from Chongming Island to Changxing Island to the No. 5 Gully LNG Station in Pudong New Area officially commenced on May 13th, marking the initiation of comprehensive construction for the project. This project signifies the first pipeline bringing natural gas from the Shanghai Natural Gas Main Pipeline Network to Chongming Island.

The extended pipeline tunnel provides an essential safeguard for Chongming’s natural gas needs. The development and functional positioning of Chongming and Changxing Islands necessitate a clean energy source like natural gas. For a considerable period, due to the lack of a direct pipeline connection, liquefied natural gas was transported to the islands via ships and tank trucks, then regasified for use. However, with the completion of major energy projects, such as the Donghai-Haimen-Chongming Island Natural Gas Pipeline, investments from Shanghai Energy Group in the Chongming Island main natural gas pipeline, the Chongming gas transmission and distribution network, and the Chongming gas power plant, Chongming Island has entered the era of piped natural gas.

Nevertheless, reliance on a single source of natural gas from the main trunk line poses risks, especially considering Changxing Island remains without piped natural gas. Additionally, although the proportion of natural gas in Shanghai’s energy consumption structure continues to rise, the Shanghai Natural Gas Main Pipeline Network along the periphery of the city has yet to form a closed loop. For instance, in the C-shaped line, the northern area has relatively weak gas receiving capabilities, and some parts of northern Pudong New Area experience low gas supply pressure.

Therefore, the construction of the Chongming Island-Changxing Island-Pudong Tunnel A project is not only a crucial guarantee for the modern ecological development of Chongming and Changxing Islands but also meets the gas demand of Changxing Island’s shipbuilding base and residents and addresses the issue of low gas supply pressure in northern Pudong New Area. Simultaneously, it ensures dual-source gas supply to the Chongming gas power plant, ensuring its safe operation and the steady development of Chongming’s economy, thus providing a gas supply guarantee for the second phase of the Chongming gas power plant’s development.

The project faces five major challenges: (1) high wear resistance and pressure requirements for shield tunneling under long-distance high water pressure, (2) ventilation difficulties in an 8.3km tunnel with a small diameter section, (3) limited efficiency of materials transportation in the long-distance small-diameter tunnel section, (4) difficulties in controlling and measuring the axis during long-distance small-diameter tunneling, and (5) adverse geological conditions when crossing the North Port of the Yangtze River between Chongming Island and Changxing Island.

To overcome these challenges, Shanghai Gas, through a rigorous assessment and preparation process, selected a leading domestic construction team through bidding. They developed multiple strategies, such as enhancing the strength and life of the cutterhead and shield tail sealing, high-efficiency tunnel relay ventilation plans, efficient pipeline segment transportation system design and manufacturing, and precision control methods for long-distance measurements and monitoring of adverse marsh gas strata.

Shanghai Gas, together with the construction unit, Shanghai Construction Machinery Group, is an expert enterprise in shield tunneling. It possesses a “full lifecycle” management and service capability for shield construction, including design, manufacturing, assembly, commissioning, construction production, transformation, and maintenance. Based on the characteristics of this cross-river pipeline project, the machinery group tailored a small-diameter shield machine with meticulous design considerations for long-distance, small-diameter, and complex geological conditions.

Currently, the Phase I and II projects of the Shanghai Natural Gas Main Pipeline Network have been completed and put into operation, strengthening Shanghai’s natural gas security. The Chongming Island-Changxing Island-Pudong New Area No. 5 Gully LNG Station pipeline project not only provides an additional “safety net” for natural gas demand on Chongming Island but also solves the issue of gas supply to Changxing Island, serving as a critical channel connecting LNG receiving stations in Jiangsu Province and Shanghai. It contributes to the formation of a complete loop for the Shanghai Natural Gas Main Pipeline Network, achieving interconnection and intercommunication of the main pipeline network in the Yangtze River Delta region, thus laying a foundation for ensuring natural gas security supply in the Yangtze River Delta region.

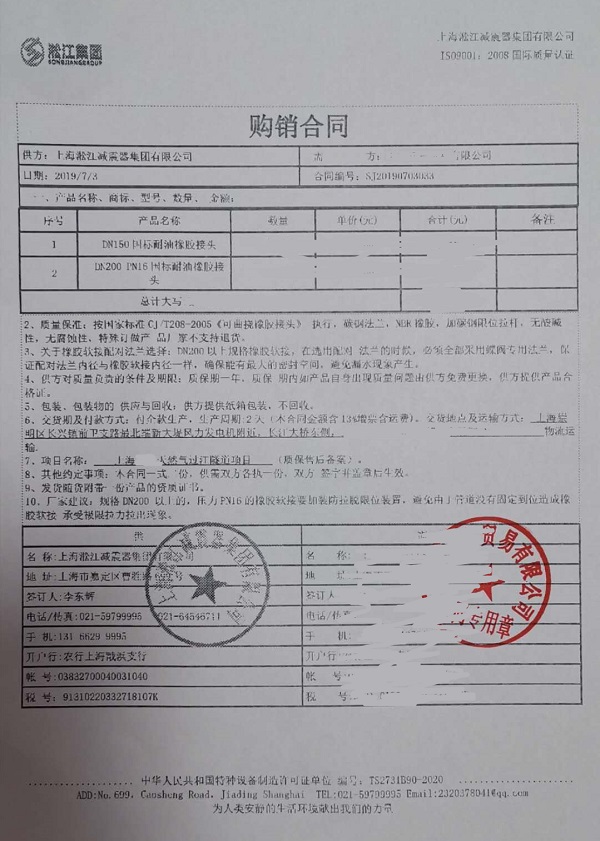

2.【Shanghai Natural Gas Cross-River Tunnel】Oil-resistant Rubber Expansion Joint Contract Scanned Document:

3.【Shanghai Natural Gas Cross-River Tunnel】Oil-resistant Rubber Expansion Joint Contract Product Image:

4.Shanghai Songjiang Vibration Absorber Co.,Ltd. Introduction:

Related link: DN50 hydraulic oil rubber shock absorber “3-year warranty”