Rubber Joint Contract for Guangzhou Toyota Automobile Factory Project

The official website of Shanghai Songjiang introduces to you: “Rubber Joint Contract Information for Guangzhou Toyota Automobile Factory Project.” We manufacture various rubber joint products, providing rubber joint products for numerous domestic automobile factories. Below is a contract case for supplying high-quality rubber joint products to Guangzhou Toyota Automobile Factory. Please do not reprint, and do not modify.

1.Guangzhou Toyota Automobile Factory Project Introduction:

Established in 2004, it has become a shining star in the southern Chinese automotive industry. In May 2006, Guangzhou Toyota Factory officially started production; in June, the domestically produced mid-to-high-end Camry was launched, winning 48 annual awards in the same year. In 2007, Camry achieved the annual sales champion in the mid-to-high-end car segment with 170,000 units sold. From 2007 to 2008, Camry held the monthly registration champion for mid-to-high-end cars for 16 consecutive months. In June 2008, just two years after its launch, Camry achieved a production and sales milestone of 300,000 units. Also in June, Guangzhou Toyota’s second product, the premium compact car Yaris, was launched. Currently, Guangzhou Toyota is constructing its second production line to expand capacity. Through an in-depth understanding of Guangzhou Toyota’s factory, the reporter hopes to discover the supporting forces behind Guangzhou Toyota’s success.

In Guangzhou Toyota’s factory located in Nansha District, Guangzhou, the reporters, guided by Guangzhou Toyota staff, visited the stamping workshop, welding workshop, and assembly workshop in the order designed by the factory for visitors. In the well-organized workshops, the production noise was significantly lower than that of other car manufacturers. Reporters were impressed by the advanced technology, strict management, and human-friendly design of Guangzhou Toyota’s factory. As a world-leading facility, Guangzhou Toyota Factory has adopted the most authentic Toyota Production System (TPS) and boasts Toyota’s globally advanced and top-notch production equipment and processes. The stamping workshop uses the world’s most advanced servo press production line with characteristics such as high efficiency, high precision, and low energy consumption. The welding workshop employs the Global Body Line (GBL) production line with 267 automated robots, ensuring precise and flexible body welding. The painting and molding workshop utilizes a robot automatic spraying system, the latest injection molding machines, and water-based paint to achieve automated and environmentally friendly production, ensuring high efficiency and quality. The assembly workshop employs Japan’s most advanced fine SPS (Set Parts Supply) part sorting system, allowing production line workers to focus on assembly work and effectively ensuring assembly quality.

Regarding quality assurance, Guangzhou Toyota follows the “quality completion from the workstation” quality management method, ensuring that each workstation strictly guarantees the quality of its manufactured products. On the welding production line, there are quality confirmation stations to inspect the products produced to prevent defective products from flowing to the next workstation. Observing the production process of “quality completion from the workstation,” visitors couldn’t help but marvel, “It is evident that the high quality of Toyota products is by no means an empty reputation.”

Even before the production of Camry, Guangzhou Toyota has been committed to building a “three-in-one” quality assurance system with “excellent products, advanced factories, and innovative channels.” The “three-in-one” quality assurance system regards products, factories, and channels as an organic whole, guided by the unified core idea of “customer first,” providing customers with comprehensive value, and establishing Camry’s comprehensive leading position from development to production, sales, and service. As Mr. Geyuan Che, General Manager of Guangzhou Toyota Motor Co., Ltd., said, “The success of Guangzhou Toyota can be attributed to the ‘three-in-one’ quality assurance system and also the result of down-to-earth, step-by-step efforts.

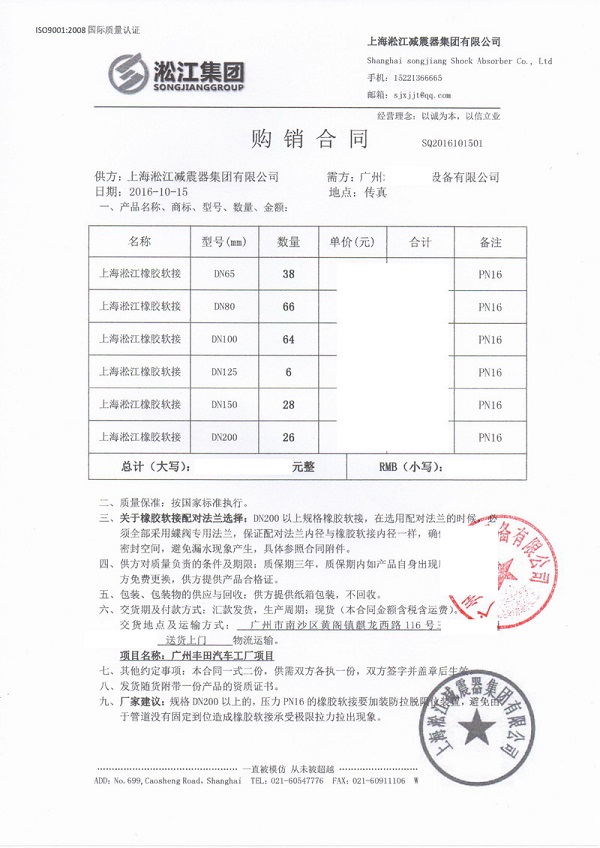

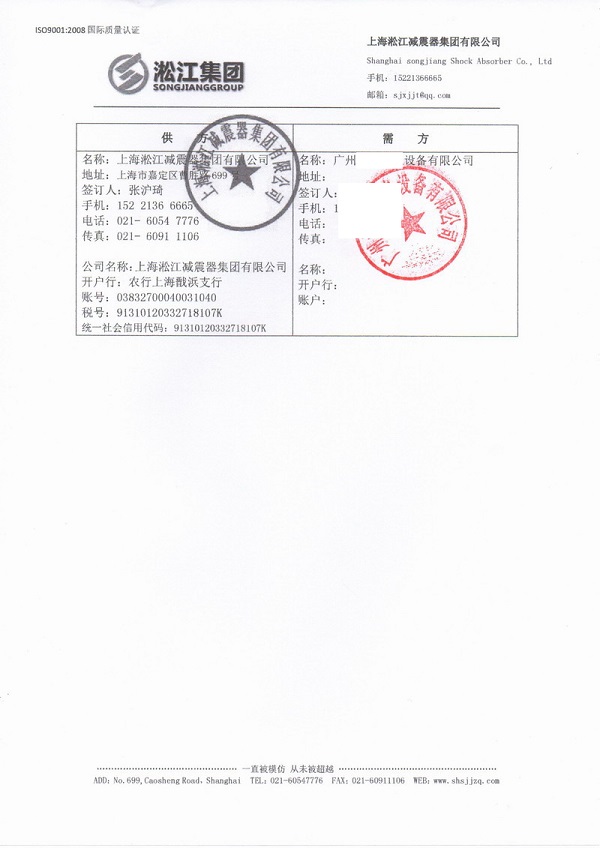

2.Inroduction to the Rubber Joint Contract for Guangzhou Toyota Automobile Factory Project:

3.Inroduction to the Rubber Joints for Guangzhou Toyota Automobile Factory Project:

4.Delivery Scene of Rubber Joints for Guangzhou Toyota Automobile Factory Project: