【CSSC International】 Rubber Joint Application – Contributing to the Chinese Shipbuilding Industry

The official website of Shanghai Songjiang Shock Absorber Group Co., Ltd. introduces: Case Study of Rubber Joint Application by CSSC International – Contributing to the Chinese Shipbuilding Industry. The following details a batch of stainless steel 304 flange rubber joint contracts supplied by Songjiang Group to CSSC International. For more information, please refer to the details below.

1. CSSC International Introduction:

CSSC International Co., Ltd. is the largest and most modern comprehensive shipbuilding and repairing enterprise in the Southern China region under China State Shipbuilding Corporation Limited. From the establishment of “Guangnan Shipyard” in 1914 to the establishment of the factory in 1954, from building only hundred-tonnage ships to constructing the first ten thousand-ton giant ship in Southern China; from the construction commencement of the Longxue base in 2004 to the integration of Longxue resources in 2012, breaking ground in the “snail shell” to achieve the breakthrough of building a 300,000-ton ship in Southern China; from the successful listing in 1993 to the expedition to Nansha in 2018, from breaking the record of building luxury passenger and roll-on/roll-off ships to mass-producing high-tech, high value-added vessels, CSSC people dare to lead and strengthen the maritime industry, always remembering the mission of “casting dreams in deep blue, protecting the vanguard, and creating an exemplary intelligent manufacturing.”

The company is located at the geometric center of the Guangdong-Hong Kong-Macao Greater Bay Area and the national-level free trade zone, covering an area of 3.02 million square meters with a deep-water dock shoreline of 5200 meters. It is equipped with two 400,000-ton shipbuilding docks, two 300,000-ton ship repair docks, two 50,000-ton shipbuilding platforms, one 900-ton gantry crane, four 600-ton gantry cranes, and multiple intelligent production lines. The annual shipbuilding capacity is 3.6 million deadweight tons, and the annual ship repair capacity is over 200 vessels, providing integrated shipbuilding and repair services. The business involves 3 major industries and 4 major sectors, with a planned South China Application Industry Center of China State Shipbuilding Corporation Limited covering an area of 600,000 square meters.

The company is a national high-tech enterprise with a nationally recognized enterprise technology center, mastering core technologies in the construction of high-tech, high value-added ship types, including a full range of liquid cargo ships, bulk carriers, luxury passenger ships and roll-on/roll-off ships, polar ships, semi-submersibles, research ships, military auxiliary ships, and special ships.

The company has the most diverse, complete, and cost-effective product lineup of liquid cargo ships, developing cutting-edge technologies such as ice strengthening, polar transport, and methanol and LNG dual-fuel propulsion, with fully independent intellectual property rights. It is a global leader in the liquid cargo ship market and excels in advanced technologies like shock absorption and noise reduction, controlling weight and center of gravity, safe return to port, and new energy power. The high-end passenger ships it has undertaken are found in the Mediterranean, Baltic, North Sea, South China Sea, and Bohai Sea. As the world’s first shipbuilder to construct advanced semi-submersibles, almost one-third of the world’s semi-submersibles are built by CSSC International, contributing China’s strength to global infrastructure construction and maritime trade.

Wenchong Shipbuilding Industry Co., Ltd., a subsidiary of CSSC International, is one of the earliest top ten ship repair companies in China that undertakes repairs of foreign ships. It is capable of repairing various types of vessels, including container ships, liquid cargo ships, heavy lift ships, roll-on/roll-off ships, semi-submersibles, luxury cruise ships, and special naval ships, with strong capabilities in desulfurization tower installation, FPSO modification, marine engineering ships, research ships, and module manufacturing.

In the application industry, the company is a major supplier of mechanical equipment and steel structure products in Southern China. It has successively undertaken well-known steel structure projects such as Humen Bridge and Macao Dream City. In 2018, it successfully undertook the steel shell manufacturing project of the Shenzhen-Zhongshan Channel immersed tube tunnel, further consolidating its market position.

As an emerging industry in CSSC International, the environmental protection industry has been strategically planned to provide customers with comprehensive solutions to environmental problems, exhibiting rapid development.

With a century of accumulation and inheritance, Guangchuan people have forged the spirit quality of “daring to lead and advance together” through the ages. Guided by the common values of “integrity-based, innovation-led, advancing together, and sharing the future,” CSSC International has always grown and progressed with its employees, sharing the fruits of development.

Looking forward and forging ahead, with the spirit of unity and hard work, facing the more difficult challenges and advancing, “becoming a first-class enterprise leading the world in technology and serving the global marine equipment and technology application industry” is the unwavering common pursuit of the new generation of Guangchuan people.

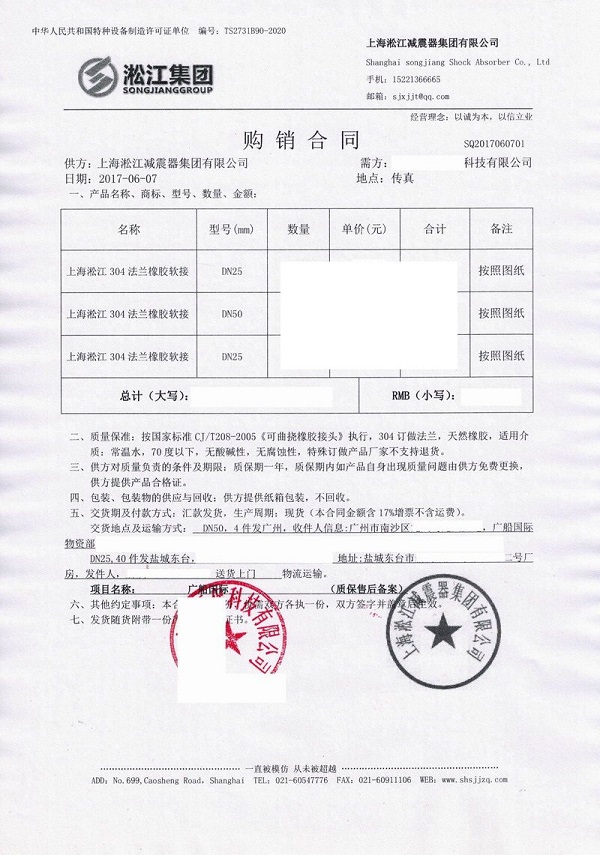

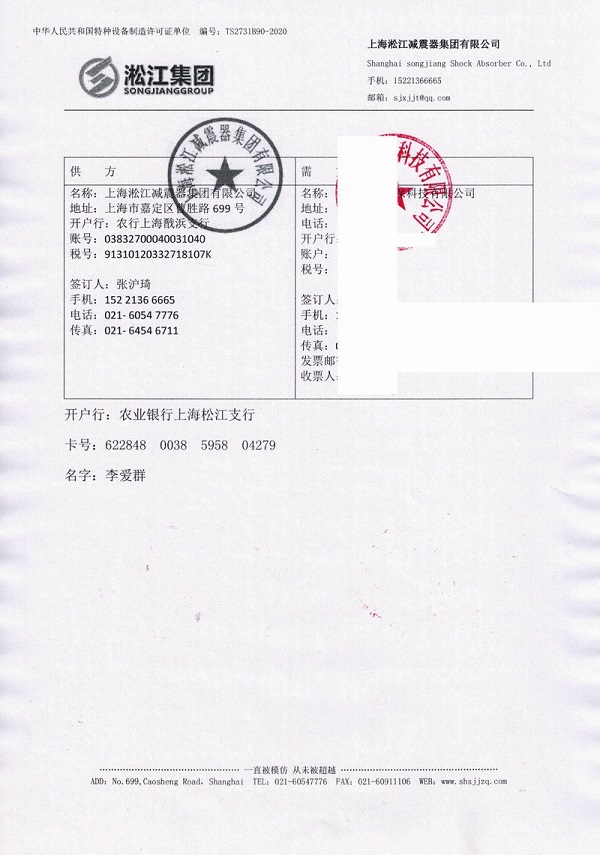

2. [CSSC International] Introduction to the Contract Case of Using Rubber Joints:

Below are scanned copies of the supply contract for CSSC International. These are genuine and valid documents. Please do not modify or reproduce them. Thank you for your cooperation. This contract is only intended as proof of supply and should not be used for other purposes.

3. What Rubber Joints are Included in the CSSC International Contract?

In this contract, we utilized stainless steel 304 flanged rubber joint products. Here is a detailed introduction:

The stainless steel 304 flanged rubber joint involves the use of stainless steel 304 material for the flange, combined with the rubber tube body, creating the stainless steel 304 flanged rubber joint.

Rubber joints primarily serve to reduce vibration and noise, effectively protecting the long-term operational life of pipelines and equipment.

Factory Introduction:

The information above on the case of ‘Guangzhou Shipyard International’ using rubber joints to contribute to the Chinese shipbuilding industry is sourced from the official website of Shanghai Songjiang Shock Absorber Group Co., Ltd., in the Marine Cases section. For more information on other marine cases, please visit the Songjiang Group Marine Cases page.

Related link: Stainless Steel 304 Rubber Joints