Contract for Rubber Joints for Jushi Group’s Jiujiang Glass Fiber Factory

The official website of Shanghai Songjiang Vibration Absorber Co.,Ltd. introduces information about the rubber joint contract for Jushi Group’s Jiujiang Glass Fiber Factory. Songjiang Group provides rubber joint products for wastewater treatment in numerous chemical fiber enterprises. These products have excellent vibration and noise reduction effects. Below is a detailed introduction.

1. Introduction to Jushi Group Jiujiang Company:

Jushi Group Jiujiang Co., Ltd. was established on December 10, 2002, registered with the Jiujiang City Administration for Industry and Commerce. The legal representative is Chu Peigen. The company’s business scope includes the production of fiberglass, composite materials, engineering plastics and products, as well as chemical raw materials for fiberglass.

2. Introduction to Jushi Group:

Jushi Group Co., Ltd. is located in the Yangtze River Delta economic zone on the northern plain of Zhejiang Province, taking advantage of a unique geographical position that has been pivotal to China’s economic development. Jushi Group is a professional manufacturer of fiberglass and a leading enterprise in the Asian fiberglass industry. For many years, it has maintained a leading position in scale, technology, market presence, and profitability. The group is a key national high-tech enterprise, ranked among the top 500 most competitive large enterprises in China, and recognized as one of the “Five Batches” key backbone enterprises and a clean factory in Zhejiang Province. It also has a corporate postdoctoral research station.

Jushi Group’s total assets exceed 15 billion RMB, employing more than 10,000 people. It has a fiberglass production capacity of over 900,000 tons and operates three domestic production bases in Tongxiang, Zhejiang; Jiujiang, Jiangxi; and Chengdu, Sichuan. Additionally, Jushi has established production and trading subsidiaries in South Africa, South Korea, Italy, Canada, India, Spain, and Hong Kong.

Jushi Group adheres to a management policy of “promoting development through technology, expanding the market through brand strength, improving efficiency through management, and strengthening the foundation through talent.” In the fields of large-scale alkali-free tank furnace, medium-alkali tank furnace, and waste silk utilization, the group possesses world-class proprietary core technologies. It has established a global marketing network and has been certified with ISO9001, ISO14001, OHSAS18001, ISO10012, and ISO17025 management systems, providing a solid guarantee for expanding and strengthening the fiberglass industry.

Jushi Group mainly produces medium and alkali-free fiberglass and its products, including alkali-free roving, chopped strand mat, continuous mat, woven roving, and chopped strand mat in both emulsion and powder form, as well as reinforcing fiberglass products like woven roving and electronic-grade fiberglass yarn and cloth. The product range covers over 20 major categories with nearly 500 specifications. The products are sold nationwide across nearly 30 provinces and cities and are exported to more than 60 countries and regions, including North America, the Middle East, Europe, Southeast Asia, and Africa, with exports accounting for more than 50% of total sales. The group’s testing center is nationally accredited by the China National Accreditation Service (CNAS). The “Jushi” brand fiberglass roving and chopped strand mat have been awarded the title of “China Famous Brand” products, with major products certified by Det Norske Veritas (DNV), Lloyd’s Register (LR), and Germanischer Lloyd (GL).

The applications of Jushi fiberglass are extensive. Reinforcing fiberglass products, as functional and structural materials, can be used in the manufacture of various profiles, pipes, pressure vessels, chemical storage tanks, sanitary ware, electrical components, ship hulls, automotive parts, and sports equipment. Electronic-grade fiberglass products are used in the production of printed circuit boards, serving as the foundational materials for various information processing devices.

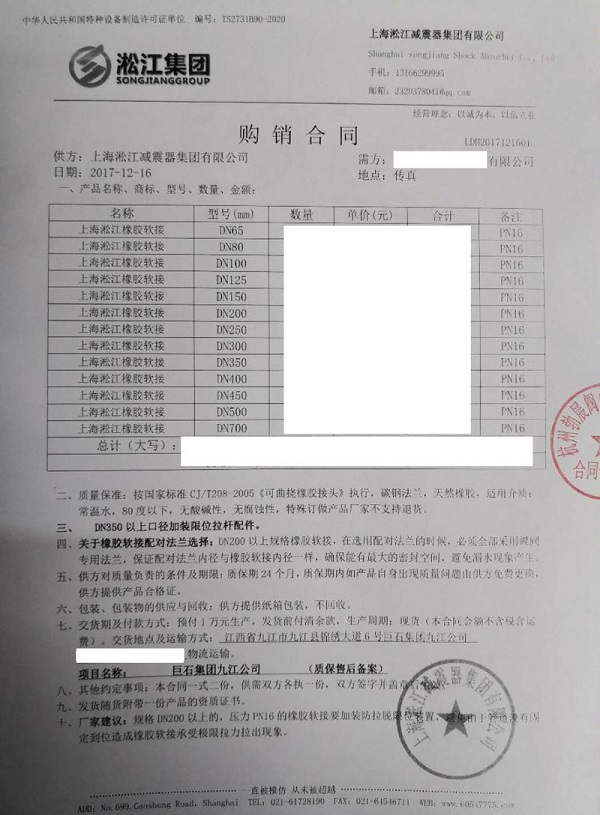

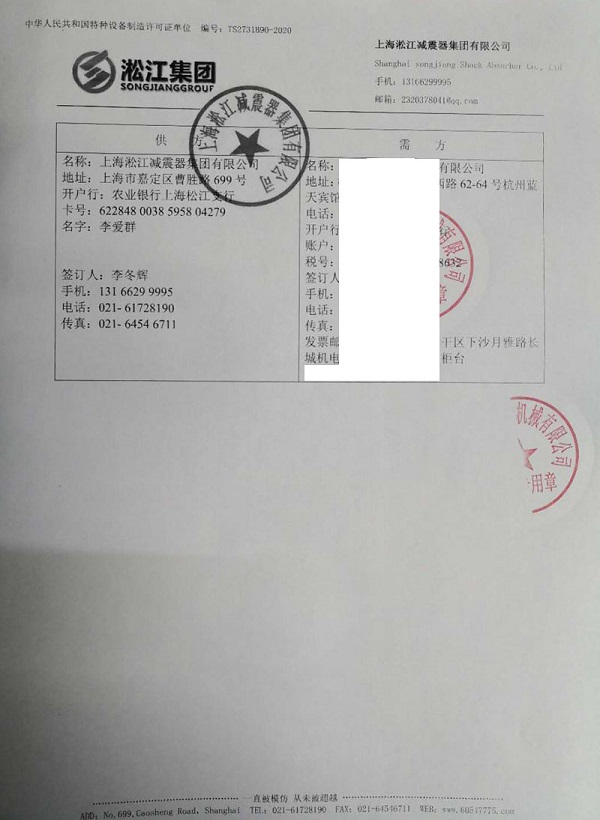

3. Introduction to the Rubber Joint Contract for Jushi Group Jiujiang Glass Fiber Factory:

The following is a scanned copy of an authentic contract. Please do not modify or reproduce it. This contract is solely for the purpose of supply verification. Thank you for your cooperation.

4. Introduction to Rubber Joints for the Jushi Group Jiujiang Glass Fiber Factory:

Compact Size, Lightweight, High Elasticity, Easy Installation and Maintenance:

The rubber joints are designed to be small in volume and light in weight, which facilitates ease of installation and maintenance. Their high elasticity allows them to adapt to various installation conditions without requiring extensive adjustments or supports.

Accommodates Lateral, Axial, and Angular Displacement:

These rubber joints can handle lateral, axial, and angular displacements, which makes them suitable for applications where pipes are not perfectly aligned or where there are discrepancies in the alignment of flanges. This flexibility ensures that the joints can accommodate various installation challenges without being constrained by misalignment issues.

Reduces Structural Noise Transmission and High Vibration Absorption:

During operation, the rubber joints significantly reduce the transmission of noise through the structure. Their excellent vibration absorption properties make them ideal for installations where noise reduction and vibration control are critical.

Produced with Premium Brand Raw Rubber, Ensuring Longevity:

The rubber joints produced by the Songjiang Group use premium brand raw rubber materials and do not incorporate recycled rubber. This commitment to quality ensures that the rubber joints have a long service life and maintain their performance over extended periods of use.

5. Shipment of Rubber Joints for Jushi Group Jiujiang Glass Fiber Factory:

6. Physical Photos of Rubber Joints for the Jushi Group Jiujiang Glass Fiber Factory:

The above information regarding the rubber joint contract for the Jushi Group Jiujiang Glass Fiber Factory comes from the case center on the official website of Shanghai Songjiang. For more information, please click: Rubber Expansion Joint Engineering Case Studies.

Relevant link: Shanghai Single-Sphere Rubber Joint.