Contract for PTFE Rubber Joints of the First Fully Hydraulic Intelligent Drilling Rig in Asia

The official website of Shanghai Songjiang Vibration Absorber Co., Ltd. introduces to you: Information on the contract for the first fully hydraulic intelligent drilling rig in Asia with PTFE rubber joints. Songjiang Group provides high-quality, oil-resistant, wear-resistant, and corrosion-resistant PTFE rubber joints for numerous oil drilling teams.

1.Introduction to the First Fully Hydraulic Intelligent Drilling Rig in Asia:

In March 2015, the first fully hydraulic intelligent drilling rig in Asia was assembled at the HBS (Sichuan Hairuike Gem Hydraulic Drilling Rig Co., Ltd.) base in Suining Economic and Technological Development Zone. It officially became operational at the Chuanqing 60001 Drilling Team in Chuanqing Chuandong Exploration.

So, where does the “intelligence” of this drilling rig lie? Xu Wei, who controls this “mechanical powerhouse,” explains, “The 22-meter stroke can be set according to the length of the drilling tool and the position of the tools. The advantage is that it is relatively safe, the equipment system is stable, and labor can be saved to the maximum extent. Once you activate its program, it will work continuously according to the set program.”

The core technology of the intelligent drilling rig lies in the automation of the drilling process. Connecting and disconnecting drill pipes, wellhead operations – none of these require human intervention. The mechanical equipment can operate according to pre-set programs. Operators only need to push buttons and monitor videos. A single shift requires only 4 people to operate, maintain, and manage the entire set of equipment, reducing the human resource allocation by nearly 60% compared to conventional drilling rigs. Additionally, the equipment can be remotely operated using an iPad.

Sichuan Hairuike Gem Hydraulic Drilling Rig Co., Ltd. (HBS), an abbreviation for the English name, is a joint venture established by Germany’s Hairuike Company, China Petroleum Baoji Petroleum Machinery Co., Ltd., and Sichuan Jing Shi Engineering Technology Co., Ltd. It is the first and largest specialized hydraulic drilling rig equipment manufacturing enterprise in China. The company, located in Suining City, Sichuan Province, at the transportation hub of the Chengdu-Chongqing economic circle, was founded in June 2015 with a registered capital of 35 million RMB. The current factory covers an area of 25,600 square meters, equipped with facilities such as workshops, office buildings, and assembly and debugging areas.

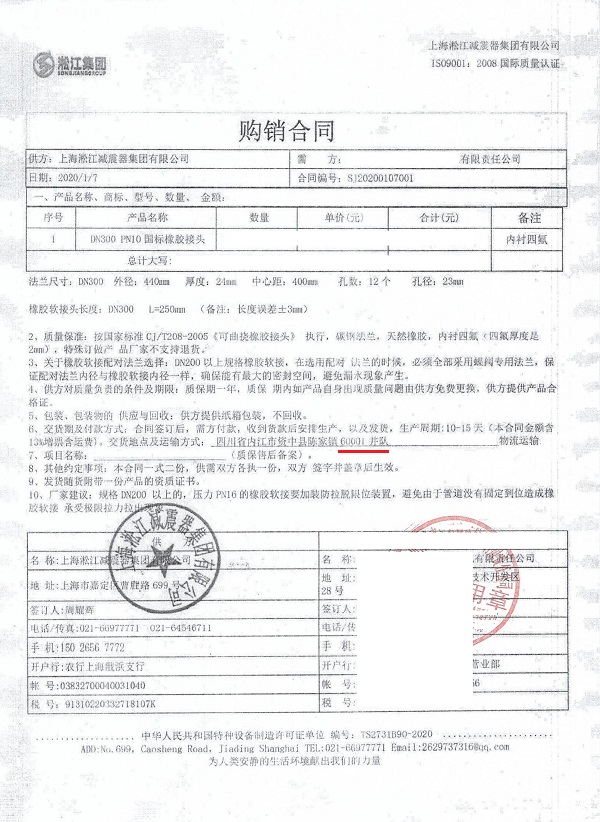

2. Introduction to the Contract for PTFE Rubber Joints of the First Fully Hydraulic Intelligent Drilling Rig in Asia:

3. Introduction to PTFE Rubber Joints of the First Fully Hydraulic Intelligent Drilling Rig in Asia:

Related Link: DN200 PTFE Rubber Joint