Contract for Hot Water Rubber Expansion Joints at Airbus Tianjin A330 Wide-body Aircraft Plant

Shanghai Songjiang Vibration Absorber Group Co., Ltd. official website introduces: information on rubber expansion joints for hot water used in the Airbus Tianjin A330 wide-body aircraft factory project. On November 25, 2016, Songjiang Group successfully won the bid for the Airbus Tianjin A330 wide-body aircraft completion and delivery center custom factory electromechanical installation project, specifically for hot water rubber expansion joint products. The installation of this project was undertaken by Tianjin Installation Engineering Co., Ltd.

Winning this project bid signifies the reliability of Songjiang Group’s vibration absorber product quality. Songjiang Group’s rubber joints, metal hoses, spring vibration absorbers, and other vibration absorber products are durable, focusing on quality and never producing low-end or inferior products. Winning customer trust with superior quality has always been the key principle.

1.Introduction to the Airbus Tianjin A330 Wide-body Aircraft Project:

The Airbus Tianjin A330 Wide-body Aircraft Completion and Delivery Center Custom Factory is a nationally significant project. It represents another important collaboration between Airbus and China in the wide-body aircraft field, following the Airbus A320 series aircraft Tianjin final assembly line. This project is located in the Tianjin Port Free Trade Zone Aviation Area, with a total investment of approximately 15.4 billion yuan. The construction land area is 339,000 square meters, and the total building area is 65,000 square meters. It consists of 10 individual buildings and outdoor infrastructure, including the completion center, paint hangar, weighing hangar, etc.

The Airbus Tianjin A330 Completion and Delivery Center is connected to the existing Airbus Tianjin A330 series aircraft Asia final assembly line and Airbus Tianjin Delivery Center. The center is responsible for tasks such as cabin installation, aircraft painting, production flight testing, customer acceptance, and aircraft delivery. Currently, more than 150 Chinese employees have completed relevant training and certification in Toulouse, France. The Airbus Tianjin A330 Completion and Delivery Center includes facilities such as the paint workshop, weighing workshop, and the main plant. The main plant covers an area of 16,800 square meters with three stations. By early 2019, the center will have over 250 employees, achieving a monthly production rate of two A330 aircraft.

Fabrice Brégier, Airbus COO and President of Commercial Aircraft, stated that the center’s commissioning and aircraft delivery mark another important milestone in the development of Airbus’ partnership with Chinese collaborators. Airbus’ long-standing cooperation with the Chinese aviation industry has expanded from the single-aisle aircraft sector to the wide-body aircraft field. The first A330 aircraft delivered at the Airbus Tianjin A330 Completion and Delivery Center is operated by Tianjin Airlines, featuring a two-class cabin layout with a total of 260 seats. This aircraft was completed jointly by Chinese employees from the center and local staff in Toulouse, France. As of the end of August 2017, Chinese airlines operate over 1,480 Airbus aircraft, including 202 A330 series aircraft. The Airbus A330 is currently the most widely operated wide-body aircraft in China.

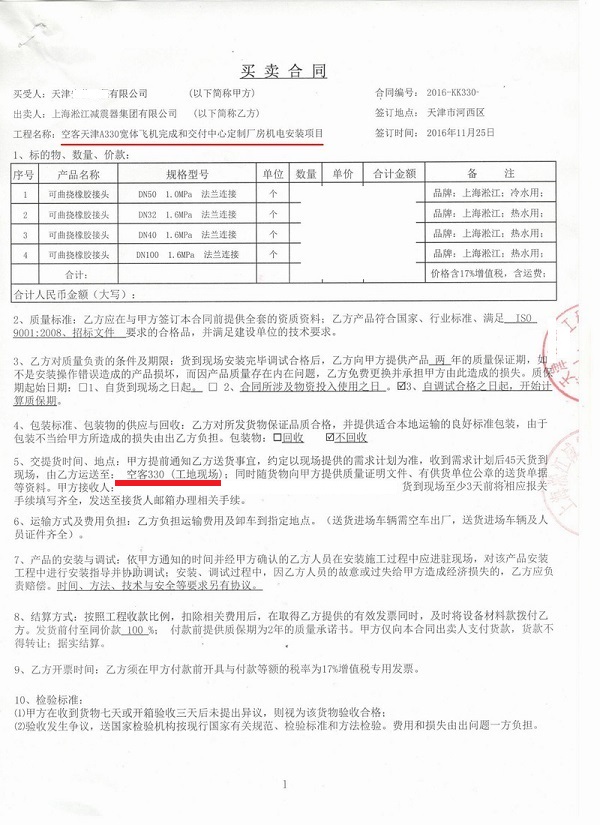

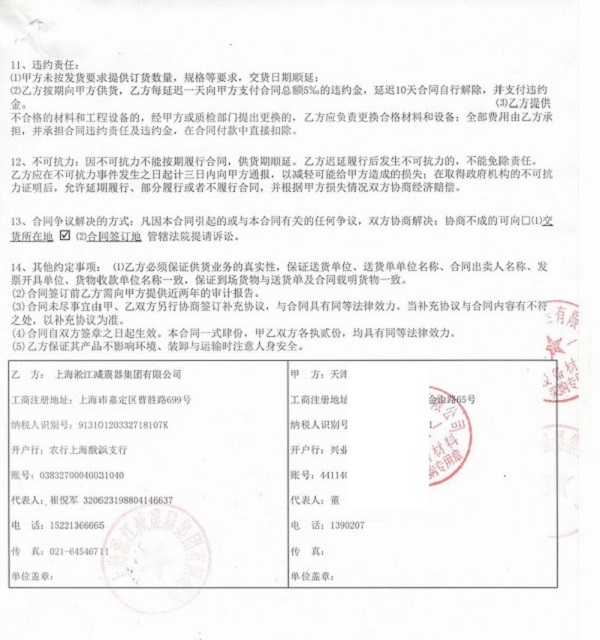

2.Introduction to the Hot Water Rubber Expansion Joint Contract for the Airbus Tianjin A330 Wide-body Aircraft Factory:

The following is a scanned copy of the contract for this project. Please do not reprint, modify, or plagiarize. Violators will be held accountable.

3.Introduction to the Hot Water Rubber Joint for the Airbus Tianjin A330 Wide-body Aircraft Factory:

Related Links:Shanghai Songjiang Company Introduction