The official website of Shanghai Songjiang introduces: We employ fully automatic vulcanization machines to control the quality of rubber joints, aligning with the “Made in China 2025” initiative. As leaders in the rubber joint industry, our factory takes proactive steps, anticipating and responding to the national 2025 intelligent manufacturing policy. We have customized fully automatic vulcanization machines to comprehensively control the quality of rubber joints.

Advantages of fully automatic vulcanization machine:

- Automatic timing control.

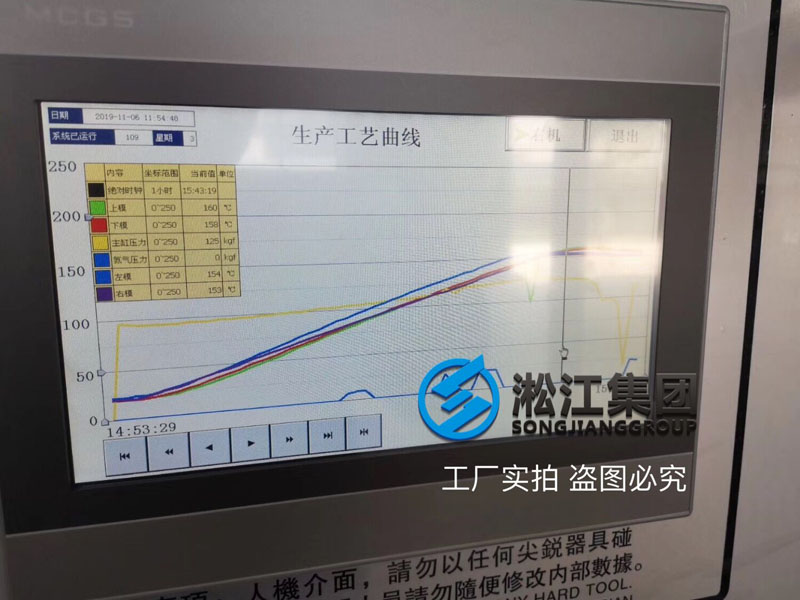

- Automatic temperature control.

- Automatic pressure control for inflation.

- Automatic mold opening at the designated time to avoid over-sulfurization or under-sulfurization.

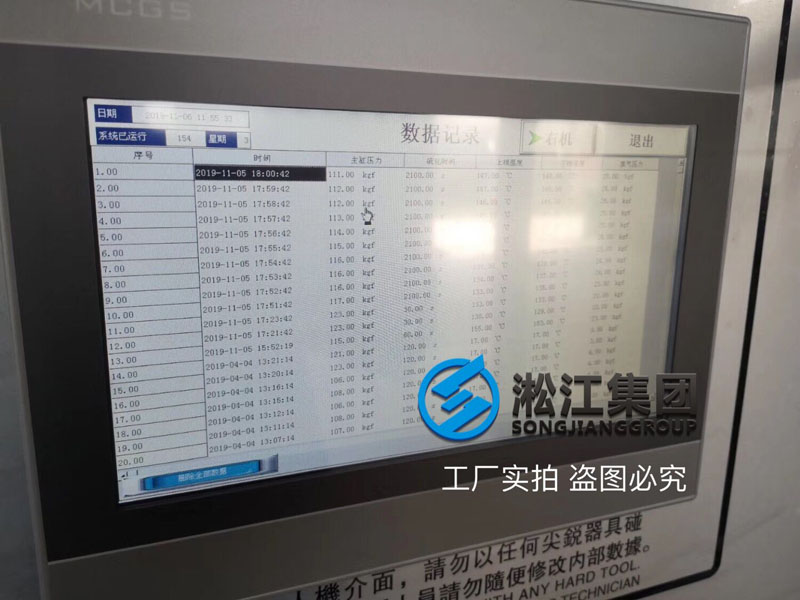

- Real-time recording of parameters such as upper and lower mold temperatures, curing time, mold pressure, inner bladder inflation pressure, etc., ensuring traceability and comprehensive control of the vulcanization process.

- Records modifications made to any parameters, ensuring accountability and preventing unauthorized alterations.

- Computer-controlled with dual-password protection for absolute confidentiality and reliability.

In summary, a true fully automatic vulcanization machine doesn’t just increase production and reduce labor; it continuously monitors and controls the production process, ensuring traceability, and recording various parameters and operations. This comprehensive control and monitoring are essential standards for supporting manufacturers. Leading the domestic rubber joint industry to align with the national 2025 intelligent manufacturing initiative is the responsibility of Shanghai Songjiang Vibration Absorber .